- [1] B. Liu, J. Qin, J. Shi, J. Jiang, X. Wu, and Z. He, (2021) “New perspectives on utilization of CO2 sequestration technologies in cement-based materials" Construction and Building Materials 272: 121660. DOI: 10.1016/j.conbuildmat.2020.121660.

- [2] A. Ahmed, (2024) “Assessing the effects of supplementary cementitious materials on concrete properties: are view" Discover Civil Engineering 1(1): 1–47. DOI: 10.1007/s44290-024-00154-z.

- [3] M. Amran, S. Debbarma, and T. Ozbakkaloglu,(2021) “Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties" Construction and Building Materials 270: 121857. DOI: 10.1016/j.conbuildmat.2020.121857.

- [4] Y.-Y. Tsai, C. I. Vazquez, R.-F. Shiu, A. K. Garcia, C. Le, P. Patel, M. Sadqi, and W.-C. Chin, (2021) “Ef fects of Rock Dust Particles on Airway Mucus Viscosity" Biotechnology and Bioprocess Engineering 26: 427 434. DOI: 10.1007/s12257-020-0236-x.

- [5] L. K. Wang, M.-H. S. Wang, and N. K. Shammas. “Agricultural waste treatment by water hyacinth aquaculture, wetland aquaculture, evapotranspiration, rapid rate land treatment, slow rate land treatment, and subsurface infiltration”. In: Waste Treatment in the Biotechnology, Agricultural and Food Indus tries: Volume 1. Springer, 2022, 277–316. DOI: 10.1007/ 978-3-031-03591-3_6.

- [6] L. A. September, N. Kheswa, N. S. Seroka, and L. Khotseng, (2023) “Green synthesis of silica and silicon from agricultural residue sugarcane bagasse ash–a mini review" RSCadvances13(2):1370–1380. DOI:10.1039/d2ra07490g.

- [7] S. E. L. Gudia, A. W. Go, M. B. Giduquio, R. G. Juanir, J. B. Jamora, C. Gunarto, and I. D. F. Tabañag, (2023) “Sugarcane bagasse ash as a partial replacement for cement in paste and mortar formulation–A case in the Philip pines" Journal of Building Engineering 76: 107221. DOI: 10.1016/j.jobe.2023.107221.

- [8] K. Vimal, K. Churi, and J. Kandasamy, (2022) “Analysing the drivers for adoption of industry 4.0 technologies in a functional paper–cement–sugar circular sharing network" Sustainable Production and Consumption 31: 459–477. DOI: 10.1016/j.spc.2022.03.006.

- [9] N. Chuewangkam, T. Nachaithong, N. Chanlek, P. Thongbai, and S. Pinitsoontorn, (2022) “Mechanical and dielectric properties of fly ash geopolymer/sugarcane bagasse ash composites" Polymers 14(6): 1140. DOI: 10. 3390/polym14061140.

- [10] N.N.Khalid, W. K. Al-Saraj, H. F. Naji, et al., (2021) “Behavior of MK-based Geopolymer Concrete Circular Columns Exposed to Fire" Journal of Applied Science and Engineering 24(1): 91–97. DOI: 10.6180/jase.202102_24(1).0012.

- [11] H. Zhang, Q. Zhang, M. Zhang, S. Tang, Y. Pei, F. Skoczylas, and S. Feng, (2024) “Effect of fly ash and metakaolin on the mechanical properties and microstructure of magnesium ammonium phosphate cement paste" Construction and Building Materials 424: 135871. DOI: 10.1016/j.conbuildmat.2024.135871.

- [12] S. S. Pradhan, S. Pramanik, U. Mishra, S. K. Biswal, and S. Thapa, (2023) “Effect of RHA on mechanical properties of GGBS based alkali activated concrete: an experimental and statistical modelling" Russian Journal of Nondestructive Testing 59(7): 767–784. DOI: 10.1134/S1061830923600375.

- [13] S. Kumar, L. Prasad, V. K. Patel, V. Kumar, A. Kumar, and A. Yadav, (2022) “Physico-mechanical properties and Taguchi optimized abrasive wear of alkali treated and fly ash reinforced Himalayan agave fiber polyester composite" Journal of Natural Fibers 19(14): 9269–9282. DOI: 10.1080/15440478.2021.1982818.

- [14] B. S. Thomas, J. Yang, K. H. Mo, J. A. Abdalla, R. A. Hawileh, and E. Ariyachandra, (2021) “Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review" Journal of Building Engineering 40: 102332. DOI: 10.1016/j.jobe.2021. 102332.

- [15] A. International. ASTM C618-22, Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. 2022.

- [16] P. Chindaprasirt and U. Rattanasak, (2020) “Eco production of silica from sugarcane bagasse ash for use as a photochromic pigment filler" Scientific reports 10(1): 9890. DOI: 10.1038/s41598-020-66885-y.

- [17] I. Phummiphan, S. Horpibulsuk, R. Rachan, A. Arul rajah, S.-L. Shen, and P. Chindaprasirt, (2018) “High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material" Journal of hazardous materials 341: 257 267. DOI: 10.1016/j.jhazmat.2017.07.067.

- [18] Y.-C. Choi, (2024) “Degree of Hydration, Microstructure, and Mechanical Properties of Cement-Modified TiO2 Nanoparticles" Materials 17(18): 4541. DOI: 10.3390/ma17184541.

- [19] B. N. Bayiha, N. Billong, E. Yamb, R. C. Kaze, and R. Nzengwa, (2019) “Effect of limestone dosages on some properties of geopolymer from thermally activated halloysite" Construction and Building Materials 217: 28–35. DOI: 10.1016/j.conbuildmat.2019.05.058.

- [20] Z. Jiang, Q. Yang, B. Wang, C. Li, J. Zhang, and Q. Ren, (2024) “Limestone filler as a mineral additive on the compressive strength and durability of self-compacting concrete with limestone manufactured sand" Journal of Building Engineering 94: 109965. DOI: 10.1016/j.jobe.2024.109965.

- [21] G. Fares, M. H. Albaroud, and M. I. Khan, (2020) “Fine limestone dust from ornamental stone factories: a potential filler in the production of High-Performance Hybrid Fiber-Reinforced Concrete" Construction and Building Materials 262: 120009. DOI: 10.1016/j.conbuildmat.2020.120009.

- [22] R. Alyousef, W. Abbass, F. Aslam, and S. A. A. Gillani, (2023) “Characterization of high-performance concrete using limestone powder and supplementary fillers in binary and ternary blends under different curing regimes" Case Studies in Construction Materials 18: e02058. DOI: 10.1016/j.jobe.2023.106180.

- [23] R. Alyousef, W. Abbass, F. Aslam, and S. A. A. Gillani, (2023) “Characterization of high-performance concrete using limestone powder and supplementary fillers in binary and ternary blends under different curing regimes" Case Studies in Construction Materials 18: e02058. DOI: 10.1016/j.cscm.2023.e02058.

- [24] A. ASTM.C109/C109M-16a Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens), ASTM International, West Conshohocken, PA, 2016. 2017.

- [25] ASTM.ASTMC348-14. 2014.

- [26] B.-h. Mo, H. Zhu, X.-m. Cui, Y. He, and S.-y. Gong, (2014) “Effect of curing temperature on geopolymerization of metakaolin-based geopolymers" Applied clay science 99: 144–148. DOI: 10.1016/j.clay.2014.06.024.

- [27] A. Akbar, F. Farooq, M. Shafique, F. Aslam, R. Alyousef, and H. Alabduljabbar, (2021) “Sugarcane bagasse ash-based engineered geopolymer mortar incorporating propylene fibers" Journal of Building Engineering 33: 101492. DOI: 10.1016/j.jobe.2020.101492.

- [28] J. L. Pastor, R. Tomás, M. Cano, A. Riquelme, and E. Gutiérrez, (2019) “Evaluation of the improvement effect of limestone powder waste in the stabilization of swelling clayey soil" Sustainability 11(3): 679. DOI: 10.3390/su11030679.

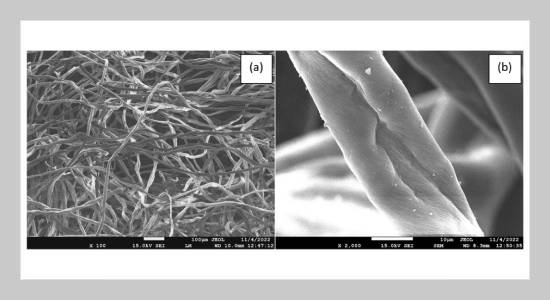

- [29] H.Abral, D. Kadriadi, A. Rodianus, P. Mastariyanto, S. Arief, S. Sapuan, M. R. Ishak, et al., (2014) “Mechanical properties of water hyacinth fibers–polyester composites before and after immersion in water" Materials & Design 58: 125–129. DOI: 10.1016/j.matdes.2014.01.043.

- [30] S. Tan and A. Supri, (2016) “Properties of low-density polyethylene/natural rubber/water hyacinth fiber composites: the effect of alkaline treatment" Polymer Bulletin 73: 539–557. DOI: 10.1007/s00289-015-1508-z.

- [31] N. H. Sari, E. Syafri, W. Fatriasari, A. Karimah, et al., (2024) “Biocomposites Based On Micro Cellulose Fibers Extracted From Paederia Foetida Stems And Investigation Of Important Properties" Journal of Applied Science and Engineering 27(9): 3261–3272. DOI: 10.6180/jase.202409_27(9).0015.

- [32] M. H. Hemida, H. Moustafa, S. Mehanny, M. Morsy, A. Dufresne, E. N. A. E. Rahman, and M. Ibrahim, (2023) “Cellulose nanocrystals from agricultural residues (Eichhornia crassipes): Extraction and characterization" Heliyon 9(6): DOI: 10.1016/j.heliyon.2023.e16436.

- [33] S. Puttala, W. Hiranphattararoj, and S. Homwutti wong, (2021) “Development of a geopolymer made from bagasse ash for use a cementitious material" Asia-Pacific Journal of Science and Technology 26(4): 10. DOI: 10.14456/apst.2021.31.

- [34] A. Sittinun, P. Pisitsak, and S. Ummartyotin, (2020) “Improving the oil sorption capability of porous polyurethane composites by the incorporation of cellulose fibers extracted from water hyacinth" Composites Communications 20: 100351. DOI: 10.1016/j.coco.2020.04.017.

- [35] S. Puttala, M. Ongwandee, K. Homwutthiwong, and S. Homwuttiwong, (2022) “STRENGTH ENHANCE MENT BY COMBINED THE CALCINED WATER SUPPLYSLUDGEINBAGASSEASHGEOPOLYMER CONCRETE":

- [36] K.-H. Yang, A.-R. Cho, and J.-K. Song, (2012) “Ef fect of water–binder ratio on the mechanical properties of calcium hydroxide-based alkali-activated slag concrete" Construction and Building Materials 29: 504–511. DOI: 10.1016/j.conbuildmat.2011.10.062.

- [37] P. Sukmak, S. Horpibulsuk, S.-L. Shen, P. Chindaprasirt, and C. Suksiripattanapong, (2013) “Factors influencing strength development in clay–fly ash geopoly mer" Construction and Building Materials 47: 1125 1136. DOI: 10.1016/j.conbuildmat.2013.05.104.

- [38] J. Wongpa, K. Kiattikomol, C. Jaturapitakkul, and P. Chindaprasirt, (2010) “Compressive strength, modulus of elasticity, and water permeability of inorganic polymer concrete" Materials & Design 31(10): 4748–4754. DOI: 10.1016/j.matdes.2010.05.012.

- [39] P. Sajan, T. Jiang, C. Lau, G. Tan, and K. Ng, (2021) “Combined effect of curing temperature, curing period and alkaline concentration on the mechanical properties of fly ash-based geopolymer" Cleaner Materials 1: 100002. DOI: 10.1016/j.clema.2021.100002.

- [40] M. Muracchioli, G. Menardi, M. D’Agostini, G. Franchin, and P. Colombo, (2023) “Modeling the com pressive strength of metakaolin-based geopolymers based on the statistical analysis of experimental data" Applied Clay Science 242: 107020. DOI: 10.1016/j.clay.2023.107020.

- [41] S. Detphan and P. Chindaprasirt, (2009) “Preparation of fly ash and rice husk ash geopolymer" International Journal ofMinerals,MetallurgyandMaterials16(6): 720–726. DOI: 10.1016/S1674-4799(10)60019-2.

- [42] C. Lv and J. Liu, (2023) “Alkaline degradation of plant fiber reinforcements in geopolymer: a review" Molecules 28(4): 1868. DOI: 10.3390/molecules28041868.

- [43] L. B. Addis, Z. B. Sendekie, and N. Satheesh, (2022) “Degradation Kinetics and Durability Enhancement Strategies of Cellulosic Fiber-Reinforced Geopolymers and Cement Composites" Advances in Materials Science and Engineering 2022(1): 1981755. DOI: 10.1155/2022/ 1981755.

- [44] H. Qu, M. Feng, M. Li, D. Tian, Y. Zhang, X. Chen, and G. Li, (2023) “Enhancing the carbonation and chloride resistance of concrete by nano-modified eco-friendly water-based organic coatings" Materials Today Communications 37: 107284. DOI: 10.1016/j.mtcomm.2023.107284.

- [45] T. S. Tie, K. H. Mo, A. Putra, S. C. Loo, U. J. Alen garam, and T.-C. Ling, (2020) “Sound absorption performance of modified concrete: A review" Journal of Building Engineering 30: 101219. DOI: 10.1016/j.jobe.2020.101219.

- [46] S. Sharma, P. Sudhakara, J. Singh, S. Singh, and G. Singh, (2023) “Emerging progressive developments in the fibrous composites for acoustic applications" Journal of Manufacturing Processes 102: 443–477. DOI: 10.1016/j.jmapro.2023.07.053.

- [47] S. Niyasom and N. Tangboriboon, (2021) “Development of biomaterial fillers using eggshells, water hyacinth fibers, and banana fibers for green concrete construction" Construction and Building Materials 283: 122627. DOI: 10.1016/j.conbuildmat.2021.122627.

- [48] A. Wongsa, R. Kunthawatwong, S. Naenudon, V. Sata, and P. Chindaprasirt, (2020) “Natural fiber reinforced high calcium fly ash geopolymer mortar" Construction and Building Materials 241: 118143. DOI: 10.1016/j.conbuildmat.2020.118143.

- [49] X. Han, P. Zhang, Y. Zheng, and J. Wang, (2023) “Utilization of municipal solid waste incineration fly ash with coal fly ash/metakaolin for geopolymer composites preparation" Construction and Building Materials 403: 133060. DOI: 10.1016/j.conbuildmat.2023.133060.

- [50] D. K. Rajak, P. H. Wagh, and E. Linul, (2022) “A re view on synthetic fibers for polymer matrix composites: performance, failure modes and applications" Materials 15(14): 4790. DOI: 10.3390/ma15144790.

- [51] M. A. Khan, B. Zhang, M. Ahmad, M. Niekurzak, M. S. Khan, M. M. Sabri Sabri, and W. Chen, (2025) “Optimizing concrete sustainability with bagasse ash and stone dust and its impact on mechanical properties and durability" Scientific reports 15(1): 1385. DOI: 10.1038/s41598-025-85363-x.

- [52] D. Glavas, G. Grolleau, and N. Mzoughi, (2023) “Greening the greenwashers–How to push greenwashers to wards more sustainable trajectories" Journal of Cleaner Production 382: 135301. DOI: 10.1016/j.jclepro.2022.135301.

- [53] P. Sangkeaw, N. Phoeychawee, C. Thongchom, J. Lawaongkerd, S. Keawsawasvong, and C. Suksiri pattanapong, (2024) “Alkaline Pretreatment Of Banana Pseudostem Waste For Green Cellulose Fiber Composite Materials" Journal of Applied Science and Engineer ing 28(2): 399–409. DOI: 10.6180/jase.202502_28(2) .0018.