- [1] F. Han, H. Wei, and Y. Liu, (2023) “Thermal Mechanical Coupling Analysis of Wheel–Rail Sliding Friction under Two-Point Contact Conditions" Lubricants 11(5): 232. DOI: 10.3390/lubricants11050232.

- [2] S. Li and D. Masse, (2019) “On the flash temperature under the starved lubrication condition of a line contact" Tribology International 136: 173–181. DOI: 10.1016/j.triboint.2019.03.038.

- [3] Y. Yang, X. Guo, L. Ling, K. Wang, and W. Zhai, (2022) “Effect of gauge corner lubrication on wheel/rail non-Hertzian contact and rail surface damage on the curves" Acta Mechanica Sinica 38(3): 521522. DOI: 10.1007/s10409-022-09002-x.

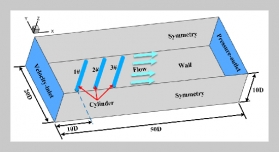

- [4] Q. Wu, M. Spiryagin, and C. Cole, (2022) “Block wheel–rail temperature assessments via longitudinal train dynamics simulations" Journal of Computational and Nonlinear Dynamics 17(11): 111007. DOI: 10.1115/1.4055431.

- [5] M. Nesluan, J. iek, K. Zgutova, P. Kejzlar, J. ramek, J. apek, P. Hruka, and O. Melikhova,(2018) “Microstruc tural transformation of a rail surface induced by severe thermoplastic deformation and its non-destructive moni toring via Barkhausen noise" Wear 402-403: 38–48. DOI: 10.1016/j.wear.2018.01.014.

- [6] M. Maglio, A. Pieringer, J. C. Nielsen, and T. Verners son, (2021) “Wheel–rail impact loads and axle bending stress simulated for generic distributions and shapes of discrete wheel tread damage" Journal of Sound and Vibration 502: 116085. DOI: 10.1016/j.jsv.2021.116085.

- [7] X. Wang, W. Dong, Q. He, B. An, H. Ding, P. Wang, W. Wang, and J. Huang, (2023) “Nonlocal thermomechanical coupled analysis of wheel-rail contact using a peridynamic model" Wear 528-529: 204954. DOI: 10.1016/j.wear.2023.204954.

- [8] L. Jing, X. Zhou, and K. Wang, (2023) “An elastic plastic theoretical analysis model of wheel-rail rolling contact behaviour" Acta Mechanica Sinica 39: 422465. DOI: 10.1007/s10409-023-22465-x.

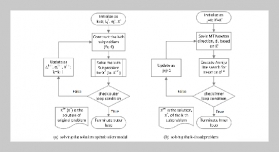

- [9] L. Yang, M. Hu, D. Zhao, J. Yang, and X. Zhou, (2020) “Thermo-mechanical analysis of train wheel-rail contact using a novel finite-element model" Industrial Lubrication and Tribology 72: 687–693. DOI: 10.1108/ILT-07 2019-0298.

- [10] P. Liu, Y. Quan, J. Wan, and L. Yu, (2020) “Experimental Investigation on the Wear and Damage Characteristics of Machined Wheel/Rail Materials under Dry Rolling-Sliding Condition" Metals 10: 472. DOI: 10.3390/met10040472.

- [11] J. Liu, P. Chen, Y. Ou, G. Zhou, P. Yu, Z. Xu, Y. Li, P. Li, C. He, X. Dai, and Y. Zhou, (2023) “Study on wear and rolling contact damage mechanism between quenched U75V rail and wheels with different microstructures" Wear 512-513: 204544. DOI: 10.1016/j.wear.2022.204544.

- [12] L. Jing, X. Su, C. Feng, and L. Zhou, (2022) “Strain rate dependent tensile behavior of railway wheel/rail steels with equivalent fatigue damage: Experiment and constitutive modeling" Engineering Fracture Mechanics 275: 108839. DOI: 10.1016/j.engfracmech.2022.108839.

- [13] S. Shrestha, M. Spiryagin, E. Bernal, Q. Wu, and C. Cole, (2023) “Recent advances in wheel-rail RCF and wear testing" Friction 11: 2181–2203. DOI: 10.1007/s40544-022-0705-7.

- [14] J. Hua, J. Liu, P. Liu, X. Zhao, C. Chen, and R. Ren, (2023) “Investigation on WEA fatigue spalling of U71MnGrail material subject to laser quenching surface treatment" Wear 512-513: 204560. DOI: 10.1016/j.wear.2022.204560.

- [15] B. Yang, S. Wang, J. Li, X. Ding, Q. Xiao, and S. Xiao, (2023) “Study on Fatigue Crack Growth in Rail Steel at Numerical and Experimental Approaches" Materials 16: 2981. DOI: 10.3390/ma16082981.

- [16] K. Knothe and S. Liebelt, (1995) “Determination of temperatures for sliding contact with applications for wheel rail systems" Wear 189: 91–99. DOI: 10.1016/0043 1648(95)06666-7.

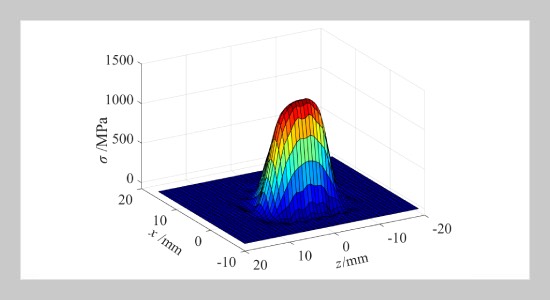

- [17] Y. Wu, Y. Wei, Y. Liu, Z. Duan, and L. Wang, (2017) “3-D analysis of thermal-mechanical behavior of wheel/rail sliding contact considering temperature characteristics of materials" Applied Thermal Engineering 115: 455 462. DOI: 10.1016/j.applthermaleng.2016.12.136.

- [18] M. Freisinger, A. Trausmuth, R. Hahn, and E. Badisch, (2024) “Influence of the evolution of near surface rail wheel microstructure on crack initiation by micro-bending investigations" Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail andRapidTransit238: 249–255. DOI: 10.1177/09544097231191550.

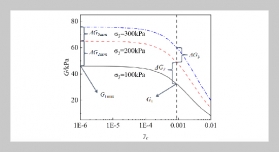

- [19] N. Zani, T. Chaise, A. Ghidini, M. Faccoli, and A. Mazzu, (2021) “Numerical study about the effect of bainitic traces on plasticity in ferritic-pearlitic railway wheels" Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit 235(6): DOI: 10.1177/0954409720960888.

- [20] J. P. Srivastava, P. K. Sarkar, and V. Ranjan, (2016) “Effects of thermal load on wheel–rail contacts: A review" Journal of Thermal Stresses 39(11): 1389–1418. DOI: 10.1080/01495739.2016.1216060.

- [21] M. Naeimi, S. Li, Z. Li, J. Wu, R. H. Petrov, J. Sietsma, and R. Dollevoet, (2018) “Thermomechanical analysis of the wheel-rail contact using a coupled modelling procedure" Tribology International 117: 250–260. DOI: 10.1016/j.triboint.2017.09.010.

- [22] J. P. Srivastava, P. K. Sarkar, M. R. Kiran, and V. Ranjan, (2019) “A numerical study on effects of friction induced thermal load for rail under varied wheel slip conditions" Simulation 95(4): 351–362. DOI: 10.1177/ 0037549718782629.

- [23] Y.-C. Chen and S.-Y. Lee, (2009) “Elastic-plastic wheel rail thermal contact on corrugated rails during wheel braking" Journal of Tribology 131(1): 1–9. DOI: 10.1115/1.2991163.