- [1] L. Huang, L. Deng, A. Wu, F. Du, X. Wang, L. Qian, and K. Lu, (2025) “Investigating hydraulic fracture penetration in soft-hard interlayer coal measures with perforated completion" Engineering Fracture Mechanics 327: 111467. DOI: 10.1016/j.engfracmech.2025.111467.

- [2] D. Liu, L. Shu, Y. Wang, X. Ni, Z. Huo, and W. Wang, (2023) “Experimental studies on the crack initiation and propagation of hydraulic fracturing with different coal structure combinations" ACS Omega 8: 38072–38082. DOI: 10.1021/acsomega.3c03999.

- [3] B. Zhang, B. Li, D. Zhang, and J. Li, (2020) “Experi mental research on permeability variation from the process of hydraulic fracturing of high-rank coal" Environmental Earth Sciences 79: 45. DOI: 10.1007/s12665-019-8764-4.

- [4] S. Lyu, S. Wang, J. Li, X. Chen, L. Chen, Q. Dong, X. Zhang, and P. Huang, (2022) “Massive hydraulic fracturing to control gas outbursts in soft coal seams" Rock Mechanics and Rock Engineering 55: 1759 1776. DOI: 10.1007/s00603-021-02734-2.

- [5] S.Yu,X.Su,J.Song,Q.Wang,andZ.You,(2025)“Theory and technology of enhanced coal seam gas production by integrated drilling, punching and fracturing in coal mine: Part 1 theory" International Journal of Coal Science & Technology 12: 57. DOI: 10.1007/s40789 025-00801-5.

- [6] S. Yu, X. Su, J. Song, Q. Wang, and Z. You, (2025) “Theory and technology of enhanced coal seam gas pro duction by integrated drilling, hydraulic punching and fracturing in coal mine: Part 2 technology" International Journal of Coal Science & Technology 12: 56. DOI: 10.1007/s40789-025-00798-x.

- [7] H. Zhao, P. Li, X. Li, and W. Yao, (2024) “Fracture propagation and evolution law of indirect fracturing in the roof of broken soft coal seams" International Journal of Coal Science & Technology 11: 4. DOI: 10.1007/s40789-023-00648-8.

- [8] W. Yang, B. Lin, Y. Gao, Y. Lv, Y. Wang, X. Mao, N. Wang, D. Wang, and Y. Wang, (2016) “Optimal coal discharge of hydraulic cutting inside coal seams for stimulating gas production: A case study in Pingmeicoalfield" Journal of Natural Gas Science and Engineering 28: 379–388. DOI: 10.1016/j.jngse.2015.12.004.

- [9] Y. Cao, J. Zhang, H. Zhai, G. Fu, L. Tian, and S. Liu, (2017) “CO2gasfracturing: A novel reservoir stimulation technology in low permeability gassy coal seams" Fuel 203: 197–207. DOI: 10.1016/j.fuel.2017.04.053.

- [10] Y. Wang, C. Zhai, T. Liu, J. Xu, W. Tang, Y. Zheng, X. Zhu, and N. Luo, (2024) “Experimental investigation of methane explosion fracturing in bedding shales: Load characteristics and three-dimensional fracture propagation" International Journal of Mining Science and Technology 34: 1365–1383. DOI: 10.1016/j.ijmst.2024.09.010.

- [11] H. Li, Q. Zhang, Z. Jiang, Y. Xu, and J. Liu, (2022) “Numerical study on the influence of coal-roof interface on vertical propagation of hydraulic fracture" International Journal of Oil, Gas and Coal Technology 29: 258 284. DOI: 10.1504/IJOGCT.2022.121053.

- [12] G. Jing and Y. Wang, (2024) “Research on hydraulic fracturing pressure relief and improvement permeability technology of the soft coal seam roof" ACS Omega 9: 2970–2979. DOI: 10.1021/acsomega.3c09020.

- [13] D. Chen, B. Jia, R. Han, L. Liu, B. Wang, X. Li, and Y. Liu, (2025) “Study on staged hydraulic sand-propped fracturing technology for gas drainage via long boreholes in coal seam roof" Physics of Fluids 37: 077154. DOI: 10.1063/5.0277686.

- [14] L.LiandW.Wu,(2021)“Variation law of roof stress and permeability enhancement effect of repeated hydraulic fracturing in low-permeability coal seam" Energy Science &Engineering 9: 1501–1516. DOI: 10.1002/ese3.909.

- [15] B. Wang, E. Hou, L. Ma, Z. Liu, T. Fan, Z. Gong, Y. Gao, W. Du, Q. Liu, and B. Ma, (2024) “Research on the law of layered fracturing in the composite roof strata of coal seams via hydraulic fracturing" Energies 17: 1941. DOI: 10.3390/en17081941.

- [16] S. Zheng, L. Wang, D. Chen, Y. Liu, and C. Jiang, (2024) “Main control factors of coalbed methane occurrence differences in adjacent coal seams- a case study of Luling coal mine, Huaibei Coalfield, China" Natural Hazards 120: 11183–11207. DOI: 10.1007/s11069-024 06636-8.

- [17] Z. Zhang, J. Ren, Y. Zhao, M. Wang, J. Yang, and C. Zhang, (2023) “Geological characteristics of low-yield and low-efficiency CBM wells and practical measures for production increase in the Qinshui Basin" ACS Omega 8: 47530–47539. DOI: 10.1021/acsomega.3c05358.

- [18] W. Wang, Y. Cheng, H. Wang, H. Liu, L. Wang, W. Li, and J. Jiang, (2015) “Fracture failure analysis of hard thick sandstone roof and its controlling effect on gas emission in underground ultra-thick coal extraction" Engineering Failure Analysis 54: 150–162. DOI: 10.1016/j. engfailanal.2015.04.016.

- [19] Y. Xuefeng, Z. Shengxian, C. Xin, Z. Jian, L. Bo, D. Jieming, Z. Ning, F. Rui, Z. Hairuo, Y. Xinyu, and W. Zhixuan, (2024) “Investigation of coal structure and its differential pore-fracture response mechanisms in the Changning Block" Processes 12: 2784. DOI: 10.3390/pr12122784.

- [20] F. Gong, J. Cheng, G. Wang, S. Peng, and Z. Zhang, (2025) “The effect of lamination on elastic anisotropy of primary coals under confining pressure: Experiment and theoretical modelling" Geophysical Prospecting 73: 1228–1242. DOI: 10.1111/1365-2478.70009.

- [21] J. Zhao, D. Tang, H. Xu, Y. Li, S. Li, S. Tao, W. Lin, and Z.Liu, (2016) “Characteristic of in situ stress and its control on the coalbed methane reservoir permeability in the eastern margin of the Ordos Basin, China" Rock Mechanics and Rock Engineering 49: 3307–3322. DOI: 10.1007/s00603-016-0969-1.

- [22] L. Huang, B. Li, B. Wang, and J. Zhang, (2023) “Effects of coal bedding dip angle on hydraulic fracturing crack propagation" Geomechanics and Geophysics for Geo-Energy and Geo-Resources 9: 30. DOI: 10.1007/s40948-023-00562-y.

- [23] S. Li, D. Tang, Z. Pan, H. Xu, S. Tao, Y. Liu, and P. Ren, (2018) “Geological conditions of deep coalbed methane in the eastern margin of the Ordos Basin, China: Implications for coalbed methane development" Journal of Natural Gas Science and Engineering 53: 394–402. DOI: 10. 1016/j.jngse.2018.03.016.

- [24] X. Yang, S. Tang, Z. Xi, S. Zhang, Q. Zhang, K. Zhang, D. Lin, and J. Wang, (2025) “Dynamic evolution and differential enrichment of deep coalbed methane: A case study in Qinshui Basin" International Journal of Coal Ge ology 299: 104696. DOI: 10.1016/j.coal.2025.104696.

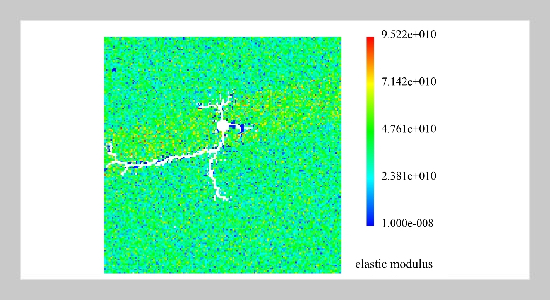

- [25] F. Zhang, D. Jiang, J. Li, and R. Wang, (2025) “Study on the influence of physical parameters of coal and rock on hydraulic fracture propagation law" Journal of Applied Science and Engineering 29: 937–943. DOI: 10.6180/jase.202603_29(4).0017.

- [26] F. Zhang, H. Wan, B. Liu, M. Zhu, X. Lv, and X. Xu, (2025) “Numerical simulation on the influence of natural fractures on hydraulic fracture propagation in fractured coal reservoirs" Energy & Fuels 39: 1938–1958. DOI: 10.1021/acs.energyfuels.4c05177.