R. K. Ranjan This email address is being protected from spambots. You need JavaScript enabled to view it.1 and S. Kumar1 1Department of Applied Mechanics and Department of Production Engineering Birla Institute of Technology, Mesra, Ranchi 835 215, Jharkhand, India

Received:

July 4, 2003

Accepted:

September 25, 2003

Publication Date:

December 1, 2004

Download Citation:

||https://doi.org/10.6180/jase.2004.7.4.04

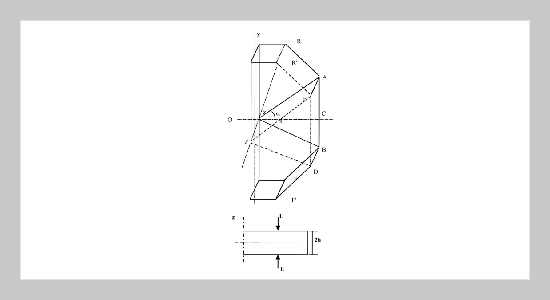

The paper reports on an investigation into the various technological aspects of a high speed forging of solid powder polygonal disc which have been compacted and sintered from atomized powder. During forging, both the bulging of sides and barreling along the thickness take place. Here solution is given for forging of an N-sided polygonal sintered disc between two flat dies at high speed, taking into account the bulging of preform. An attempt has been made for the development of a generalized solution for the polygonal disc and determination of the die pressures developed during the cold forging of square sintered powder preform by using an upper bound approach. The results so obtained are discussed critically to illustrate the interaction of various process parameters involved and are presented graphicallyABSTRACT

Keywords:

Preform, Sintering, Interfacial Friction Law, Yield Criteria

REFERENCES