Jiun-Min Wang1 and Lung-Jieh Yang This email address is being protected from spambots. You need JavaScript enabled to view it.1 1Department of Mechanical and Electro-Mechanical Engineering, Tamkang University Tamsui, Taiwan 251, R.O.C.

Received:

January 10, 2005

Accepted:

March 21, 2005

Publication Date:

September 1, 2005

Download Citation:

||https://doi.org/10.6180/jase.2005.8.3.09

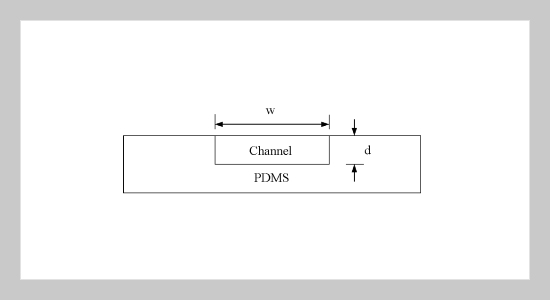

This paper describes an ejection-type electro-hydro-dynamic (EHD) micropump using various types of polymers to protect the electrodes. The polymer layers of parylene and crosslinked gelatin were shown to protect the gold electrodes from electrolytic aging. The pump chip is packaged by the polydimethylsiloxane (PDMS) bonding technique. The results show that the polymer protection layers are successful in prolonging the operation lifetime. They can also provide the inner walls of channels with different surface properties for the working liquid to be driven through.ABSTRACT

Keywords:

Parylene, Gelatin, Surface Modification, Electro-Hydro-Dynamic (EHD)

REFERENCES