Fung-Huei Yeh This email address is being protected from spambots. You need JavaScript enabled to view it.1, Ching-Lun Li1 and Kun-Nan Tsay1 1Department of Mechanical and Electro-Mechanical Engineering, Tamkang University, Tamsui, Taiwan 251, R.O.C.

Received:

March 8, 2011

Accepted:

September 16, 2011

Publication Date:

March 1, 2012

Download Citation:

||https://doi.org/10.6180/jase.2012.15.1.04

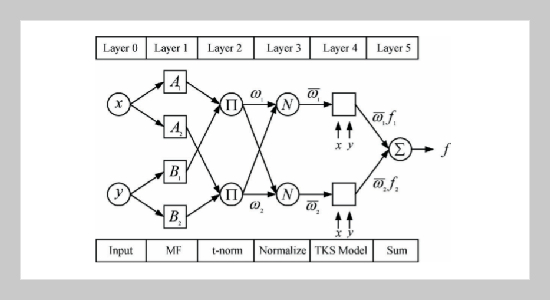

This paper combines adaptive network fuzzy inference system (ANFIS) and finite element method (FEM) to study the die shape optimal design in sheet metal bending process. At first, the explicit dynamic FEM is used to simulate the sheet metal bending process. After the bending process, the springback is analyzed by using the implicit static FEM to establish the basic database for ANFIS. Then, the die shape optimal design is performed by ANFIS using this database in the sheet metal bending process. As a verification of this system, the L-type and V-type dies are designed for the experiments to prove the reliability of FEM analysis and ANFIS optimal design by comparing the punch load and stroke relationship, the deformation history, stress distribution, and the bending angle of workpiece after springback between numerical and experimental results. It shows that a good agreement is achieved from comparison between numerical and experimental results. From this investigation, ANFIS has proved to be a useful scheme for die shape optimal design in the metal forming category.ABSTRACT

Keywords:

Adaptive Network Fuzzy Inference System, Finite Element Method, Die Shape Optimal Design, Springback, Sheet Metal Bending Process

REFERENCES