- [1] M.L.S. Ali Alsaleh, (2014) “Waste Tire Pyrolysis: Influential Parameters and Product Properties" Current Sustainable/Renewable Energy Reports 1: 129–135. DOI: 10.1007/s40518-014-0019-0.

- [2] A. A. Melik Bekhiti Habib Trouzine,(2014)“Properties of Waste Tire Rubber Powder" Engineering, Technology & Applied Science Research 3: 669–672. DOI: 10.48084/etasr.439.

- [3] M. S. Abbas-Abadi, M. Kusenberg, H. M. Shirazi, B. Goshayeshi, and K. M. Geem, (2022) “Towards full recyclability of end-of-life tires: Challenges and opportuni ties" Journal of Cleaner Production 374: 134036. DOI: 10.1016/j.jclepro.2022.134036.

- [4] N. H. Habiba Afrin and R. Abbasi, (2021) “Study on End-of-Life Tires (ELTs) Recycling Strategy and Applications" IOP Conference Series: Materials Science and Engineering 1200: 012009. DOI: 10.1088/1757 899X/1200/1/012009.

- [5] W. Chen, B. Liu, G. Luo, C. Yuwen, F. Peng, S. Gong, K. Hou, Y. An, G. Ji, and B. Wu, (2024) “KOH etching catalyzed microwave pyrolysis of waste tires to prepare porous graphene" Carbon Letters 34: 2195–2209. DOI: 10.1007/s42823-024-00804-3.

- [6] M. Idrees, F. Saeed, A. Amin, and T. Hussain, (2021) “Improvement in compressive strength of Styrene Butadiene-Rubber (SBR) modified mortars by using pow der form and nanoparticles" Journal of Building Engineering 44: 102651. DOI: 10.1016/j.jobe.2021. 102651.

- [7] I. Ban, I. Bariši´c, M. Cuculi´c, and M. Zvonari´c, (2025) “Performance Evaluation of Waste Rubber-Modified Asphalt Mixtures: A Comparative Study of Asphalt Concrete and Stone Mastic Asphalt Gradings" Infrastructures 15: 107. DOI: 10.3390/infrastructures10050107.

- [8] F. S. Shahar, M. T. H. Sultan, A. U. M. Shah, and S. N. A. Safri, (2020) “A Comparative Analysis between Conventional Manufacturing and Additive Manufacturing of Ankle-Foot Orthosis" Applied Science and Engineering Progress 13: 96–103. DOI: 10.14416/j.asep.2020.03.002.

- [9] H. T. Nguyen, K. Crittenden, L. Weiss, and H. Bar daweel, (2022) “Recycle of waste tire rubber in a 3D printed composite with enhanced damping properties" Journal of Cleaner Production 368: 133085. DOI: 10.1016/j.jclepro.2022.133085.

- [10] F. M. Vedat Cavus, (2020) “Effect of wood particle size on selected properties of neat and recycled wood polypropylene composites" Bio Resources 15: 3427–3442. DOI: 10.15376/biores.15.2.3427-3442.

- [11] E. Nezbedov, F. Krcma, Z. Majer, and P. Hutar, (2016) “Effect of particles size on mechanical properties of polypropylene particulate composites" International Journal of Structural Integrity 7: 690–699. DOI: 10.1108/IJSI-09-2015-0030.

- [12] N. Buddhacosa, J. Galos, A. Khatibi, R. Das, and E. Kandare, (2024) “Effect of tyre-derived rubber particle size on the mechanical properties of rubberised syntactic foam" Cleaner Materials 11: 100223. DOI: 10. 1016/j.clema.2024.100223.

- [13] A. A. A. Abdelmagid, A. I. B. Idriss, and C.-M. Yang, (2024) “Effects of Particle Size on Mechanical Proper ties and Forming Accuracy of Prosopis chilensis Powder/Polyethersulfone Composites Produced via Selective Laser Sintering" Polymers 16: 1786. DOI: 10. 3390/polym16131786.

- [14] S. S. and Ali H. Al-Marzouqi, M. Z. Iqbal, and W. Ahmed, (2022) “Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polymeric Based Composite Material" Polymers 14: 4830. DOI: 10. 3390/polym14224830.

- [15] W.A.E.-S. B. Ahmed Ebrahim Abu El-Maaty Ibrahim Reda Ibrahim Sourour, (2020) “Using of Plastic Wastes as Additives in Bituminous Mixes" Applied Science and Engineering Progress 14: 131–141. DOI: 10.14416/j.asep.2020.11.003.

- [16] P. N. B. R. Paulo Santos Abílio P. Silva, (2024) “The Effect of Carbon Nanofibers on the Mechanical Performance of Epoxy-Based Composites: A Review" Polymers 16: 2152. DOI: 10.3390/polym16152152.

- [17] N. vande Werken, P. Koirala, J. Ghorbani, D. Doyle, and M.Tehrani, (2021) “Investigating the hot isostatic pressing of an additively manufactured continuous carbon fiber reinforced PEEK composite" Additive Manufacturing 37: 101634. DOI: 10.1016/j.addma. 2020.101634.

- [18] M. C. deSouza, I. Moroz, I. Cesarino, A. L. Leão, M. Jawaid, and O. A. T. Dias, (2022) “A Review of Natural Fibers Reinforced Composites for Railroad Applications" Applied Science and Engineering 15: 1–12. DOI: 10.14416/j.asep.2022.03.001.

- [19] W. W. R. Ganjar Pramudi and D. Ariawan, (2021) “Investigation of Flexural strength of Sandwich Panels Recycled Carbon Fibre/Polyester with Cotton Mesh Fabric Reinforcement in Polyurethane Core" Journal Applied Science and Engineering 25: 975–983. DOI: 10.6180/jase.202210_25(5).0013.

- [20] A.Shrivastava, (2018) “2- Polymerization" Introduction to Plastics Engineering: 17–48. DOI: doi.org/10. 1016/B978-0-323-39500-7.00002-2.

- [21] Y. Zhong, J. Gao, Z. Wang, and Z. Guo, (2017) “Influence of Particle Size Distribution on Agglomeration/defluidization of Iron Powders at Elevated Temperature" ISIJ International 57: 649–455. DOI: 10.2355/isijinternational.ISIJINT-2016-487.

- [22] D. R. Ali Fazli, (2021) “Phase morphology, mechanical, and thermal properties of fiber-reinforced thermoplastic elastomer: Effects of blend composition and compatibilization" Journal of Reinforced Plastics and Composites 41: 267–283. DOI: 10.1177/ 07316844211051749.

- [23] A. Ko´sciuszko, D. Sykutera, P. Czy˙ zewski, S. Hoyer, and B. S. Lothar Kroll, (2022) “Processing and Mechanical Properties of Highly Filled PP/GTR Compounds" Ma terials 15: 3390. DOI: 10.3390/ma15113799.

- [24] X. Yuan, B. Zhu, X. Cai, S. Zhao, K. Qiao, and M. Zhang, (2017) “Effects of particle size and distribution of the sizing agent on carbon fiber/epoxy composites interfa cial adhesion" Polymer Composite 39: E2036–E2045. DOI: 10.1002/pc.24439.

- [25] M. A. Ashraf, W. Peng, Y. Zare, and K. Y. Rhee, (2018) “Effects of Size and Aggregation/Agglomeration of Nanoparticles on the Interfacial/Interphase Properties and Tensile Strength of Polymer Nanocomposites" Nanoscale Research Letters 13: 214. DOI: 10.1186/ s11671-018-2624-0.

- [26] Z.-h. Gao, H.-j. Gao, Y.-d. Zhang, Q. Wu, S.-g. Chen, and X. Zhou, (2022) “Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles" Nanotechnology Reviews 11: 1854–1869. DOI: doi.org/10.1515/ntrev-2022 0112.

- [27] C. Budiyantoro, A. W. N. Sudarisman, Z. Ilyas, and B. Bilyferdin, “Optimization Of Wood Powder Particle Size And Weight Fraction For Enhancing The Mechanical Properties Of Wood Plastic Composites Using Recycled EPS Matrix" Journal of Applied Science and Engineering 28(12): 2515–2523. DOI: 10.6180/jase.202512_28(12).0019.

- [28] E. D. Aboulfazl Barati Deacon S.Godfrey, (2025) “Development of Toughened Recycled Polyethylene Terephthalate and Micronized Rubber Composites for 3D Printing Applications: Compatibilization Strategies and Performance Assessment" ACS Omega 10: 18404–18418. DOI: 10.1021/acsomega.4c10726.

- [29] X. Zhan, K. Su, X. Tuo, and Y. Gong, (2024) “Mechanical, Thermal, and Electrical Properties on 3D Printed Short Carbon Fiber Reinforced Polypropylene Compos ites" ACS Applied Polymer Materials 6: 3787–3795. DOI: 10.1021/acsapm.3c03083.

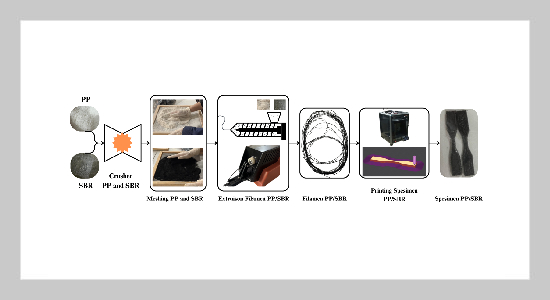

- [30] I. Ardhiansyah, G. Pramudi, D. Ariawan, H. I. Akbar, and R. B. Kristiawan, (2025) “Investigation Influence of Styrene Butadiene Rubber on Physical, Mechanical and Thermal Properties of Polypropylene Composite for 3DPrinting Filaments" Engineering, Technology & Applied Science Research 15: 27793–27799. DOI: 10.48084/etasr.13059.

- [31] T.-C. Chiang, H.-L. Liu, L.-C. Tsai, T. Jiang, N. Ma, and F.-C. Tsai, (2020) “Improvement of the mechanical property and thermal stability of polypropylene/recycled rubber composite by chemical modification and physical blending" Scientific Reports 10: 2432. DOI: 10.1038/s41598-020-59191-0.

- [32] N.A.-Z. Parisa Khoshnoud, (2018) “The effect of particle size of fly ash (FA) on the interfacial interaction and performance of PVC/FA composites" Journal of Vinyl &Additive Technology 25: 134–143. DOI: 10.1002/vnl.21633.

- [33] Q. F. Gillani, F. Ahmad, M. I. A. Mutalib, and E. Sya hera, (2016) “Thermal Degradation and Char Morphology of HNTs Reinforced Epoxy Based Intumescent Fire Retardant Coatings" Key Engineering Materials 701: 83–88. DOI: 10.4028/www.scientific.net/KEM.701.83.

- [34] J. P. Mofokeng and A. S. Luyt, (2015) “Morphology and thermal degradation studies of melt mixed poly (hydroxybutyrate-co-valerate)(PHBV)/poly (ε-caprolactone)(PCL) biodegradable polymer blend nanocomposites with TiO2 as filler" Journal of Mate rials Science 50: 3812–3824. DOI: 10.1007/ s10853-015-8950-z.

- [35] B. K. C. Soumyajyoti Biswas Purusattam Ray, (2015) “Dislocation Dynamics and Ductile Fracture": Chapter 9. DOI: 10.1002/9783527672646.ch9.

- [36] N. H. Sari, S. Suteja, A. Fudholi, A. Zamzuriadi, E. D. Sulistyowati, P. Pandiatmi, S. Sinarep, and A. Zainuri, (2021) “Morphology and mechanical properties of coconut shell powder-filled untreated cornhusk fibre-unsaturated polyester composites" Polymer 222: 123657. DOI: 10.1016/j.polymer.2021.123657.