Jong Ho Hwang1, Yeon U Gu 2, Ogah Friday Imhanmhenisi2, Sang Un Gong3, Yong Ha Kwon3 and Jong Soo Kim This email address is being protected from spambots. You need JavaScript enabled to view it.3 1Kyungdong R&H CO., LTD, Uijeon-ri, Jinyeong-eup, Gimhae-si, Gyeongsangnam-do 621-801, Rep of Korea

2Department of Refrigeration and Air-Conditioning Engineering, Graduate School, Pukyong National University (PKNU), Yongdang-dong, Nam-gu, Busan 608-739, Rep of Korea

3Departement of Refrigeration and Air-Conditioning Engineering, PKNU, Rep of Korea

Received:

May 9, 2012

Accepted:

June 4, 2012

Publication Date:

June 4, 2012

Download Citation:

||https://doi.org/10.6180/jase.2012.15.2.03

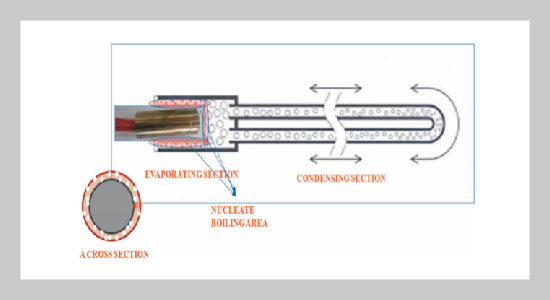

The unit coolers of cold storage warehouse should be defrosted at least once every 3 to 6 hours. Electric resistance heaters are frequently employed for the defrosting of unit coolers. The most important problems of electric defrosting are defrosting time and changes in room temperature. We developed a high efficient defrosting method using the Bubble Jet Loop Heat Pipe (BJLHP). This study shows a comparison between conventional electric heater and Bubble Jet Loop Heat Pipe (BJLHP) as a defrost device in evaporator. “The factors evaporator temperatures, cold room temperature, heater temperature, defrost water quantity and electric power consumption were compared” The defrosting method using “Bubble Jet Loop Heat Pipe (BJLHP)” shows lower cold storage room temperature and electric power consumption than the conventional electric defrosting heater.ABSTRACT

Keywords:

Bubble Jet Loop Heat Pipe (BJLHP), Optimum Working Fluid Charging Rate, Unit Cooler, Defrost Water Quantity, Electric Defrosting Heater, Electric Power Consumption

REFERENCES