- [1] J. Tang, (2020) “Carbon nanotube-based flexible electron�ics" Flexible, Wearable, and Stretchable Electronics: 137–156. DOI: 10.1201/9780429263941-5.

- [2] R. Maheswaran and B. P. Shanmugavel, (2022) “A crit�ical review of the role of carbon nanotubes in the progress of next-generation electronic applications" Journal of Electronic Materials 51(6): 2786–2800. DOI: 10.1007/S11664-022-09516-8.

- [3] S. Zhu, J. Sheng, Y. Chen, J. Ni, and Y. Li, (2021) “Carbon nanotubes for flexible batteries: recent progress and future perspective" National Science Review 8(5): nwaa261. DOI: 10.1093/nsr/nwaa261.

- [4] R. Amin, P. R. Kumar, and I. Belharouak. Carbon Nanotubes–Redefining the World of Electronics. 2020.

- [5] E. Vázquez and M. Prato, (2010) “Functionalization of carbon nanotubes for applications in materials science and nanomedicine" Pure and Applied Chemistry 82(4): 853–861. DOI: 10.1351/PAC-CON-09-10-40/html.

- [6] B. O. Murjani, P. S. Kadu, M. Bansod, S. S. Vaidya, and M. D. Yadav, (2022) “Carbon nanotubes in biomedi�cal applications: current status, promises, and challenges" Carbon Letters 32(5): 1207–1226. DOI: 10.1007/s42823-022-00364-4.

- [7] V. Raphey, T. Henna, K. Nivitha, P. Mufeedha, C. Sabu, and K. Pramod, (2019) “Advanced biomedical applications of carbon nanotube" Materials Science and Engineering: C 100: 616–630. DOI: 10.1016/j.msec.2019.03.043.

- [8] M.-S. Hong, Y. Park, T. Kim, K. Kim, and J.-G. Kim, (2020) “Polydopamine/carbon nanotube nanocomposite coating for corrosion resistance" Journal of Materi�omics 6(1): 158–166. DOI: 10.1016/j.jmat.2020.01.004.

- [9] A. Kubley, M. Chitranshi, X. Hou, and M. Schulz, (2021) “Manufacturing and Characterization of Cus�tomizable Flexible Carbon Nanotube Fabrics for Smart Wearable Applications" Textiles 1(3): 534–546. DOI: 10.3390/textiles1030028.

- [10] M. Romero-Sáez, A. Dongil, N. Benito, R. Espinoza�González, N. Escalona, and F. Gracia, (2018) “CO2 methanation over nickel-ZrO2 catalyst supported on car�bon nanotubes: A comparison between two impregnation strategies" Applied Catalysis B: Environmental 237: 817–825. DOI: 10.1016/j.apcatb.2018.06.045.

- [11] K. S. Ibrahim, (2013) “Carbon nanotubes? properties and applications: A review" Carbon letters 14(3): 131–144. DOI: 10.5714/CL.2013.14.3.131.

- [12] D. R. Minett, J. P. O’Byrne, M. D. Jones, V. P. Ting, T. J. Mays, and D. Mattia, (2013) “One-step production of monolith-supported long carbon nanotube arrays" Car�bon 51: 327–334. DOI: 10.1016/j.carbon.2012.08.060.

- [13] M. Mohammad, A. A. Moosa, J. Potgieter, and M. K. Ismael, (2013) “Carbon nanotubes synthesis via arc dis�charge with a Yttria catalyst" International Scholarly Research Notices 2013: DOI: 10.1155/2013/785160.

- [14] M. C. Paladugu, K. Maneesh, P. K. Nair, and P. Hari�doss, (2005) “Synthesis of carbon nanotubes by arc dis�charge in open air" Journal of nanoscience and nan�otechnology 5(5): 747–752. DOI: 10.1166/jnn.2005.108.

- [15] J. Chrzanowska, J. Hoffman, A. Małolepszy, M. Mazurkiewicz, T. A. Kowalewski, Z. Szymanski, and L. Stobinski, (2015) “Synthesis of carbon nanotubes by the laser ablation method: Effect of laser wavelength" physica status solidi (b) 252(8): 1860–1867. DOI: 10.1002/pssb.201451614.

- [16] T. Kuo, C. Chi, and I. Lin, (2001) “Synthesis of carbon nanotubes by laser ablation of graphites at room tempera�ture" Japanese Journal of Applied Physics 40(12R): 7147. DOI: 10.1143/JJAP.40.7147.

- [17] N. De Greef, L. Zhang, A. Magrez, L. Forró, J.-P. Loc�quet, I. Verpoest, and J. W. Seo, (2015) “Direct growth of carbon nanotubes on carbon fibers: Effect of the CVD parameters on the degradation of mechanical properties of carbon fibers" Diamond and Related Materials 51: 39–48. DOI: 10.1016/j.diamond.2014.11.002.

- [18] W. Zhang, H. Xie, R. Zhang, M. Jian, C. Wang, Q. Zheng, F. Wei, and Y. Zhang, (2015) “Synthesis of three�dimensional carbon nanotube/graphene hybrid materials by a two-step chemical vapor deposition process" Carbon 86: 358–362. DOI: 10.1016/j.carbon.2015.01.051.

- [19] A. Eatemadi, H. Daraee, H. Karimkhanloo, M. Kouhi, N. Zarghami, A. Akbarzadeh, M. Abasi, Y. Hanifeh�pour, and S. W. Joo, (2014) “Carbon nanotubes: prop�erties, synthesis, purification, and medical applications" Nanoscale research letters 9: 1–13. DOI: 10.1186/1556-276x-9-393.

- [20] J. A. Isaacs, A. Tanwani, M. Healy, and L. Dahlben, (2010) “Economic assessment of single-walled carbon nan�otube processes" Journal of Nanoparticle Research 12: 551–562. DOI: 10.1007/s11051-009-9673-3.

- [21] R. Zhang, Y. Zhang, and F. Wei, (2017) “Horizontally aligned carbon nanotube arrays: growth mechanism, con�trolled synthesis, characterization, properties and applica�tions" Chemical Society Reviews 46(12): 3661–3715. DOI: 10.1039/C7CS00104E.

- [22] I. Levchenko, Z. Han, S. Kumar, S. Yick, J. Fang, and K. Ostrikov. “Large arrays and networks of carbon nanotubes: morphology control by process param�eters”. In: Syntheses and Applications of Carbon Nan�otubes and Their Composites. IntechOpen, 2013. DOI: 10.5772/52674.

- [23] C.-M. Seah, S.-P. Chai, and A. R. Mohamed, (2011) “Synthesis of aligned carbon nanotubes" Carbon 49(14): 4613–4635. DOI: 10.1016/j.carbon.2011.06.090.

- [24] A. Melezhik, M. Smykov, E. Y. Filatova, A. Shuklinov, R. Stolyarov, I. Larionova, and A. Tkachov, (2013) “Synthesis of carbon nanotubes from acetone" Theoretical Foundations of Chemical Engineering 47: 435–443. DOI: 10.1134/S0040579513040131.

- [25] D. Ping, C. Wang, X. Dong, and Y. Dong, (2016) “Co�production of hydrogen and carbon nanotubes on nickel foam via methane catalytic decomposition" Applied Sur�face Science 369: 299–307. DOI: 10.1016/j.apsusc.2016.02.074.

- [26] G. Messina, S. Santangelo, M. G. Donato, M. Lanza, C. Milone, A. Pistone, and S. Galvagno, (2008) “Multi�walled carbon nanotubes production by ethane decomposi�tion over silica-supported iron-catalysts" physica status solidi (a) 205(10): 2422–2427. DOI: 10.1002/pssa.200723647.

- [27] M. Zdrojek, J. Sobieski, A. Duzynska, and J. Judek, (2015) “Synthesis of Carbon Nanotubes from Propane ÃÃ" Chem. Vap. Deposition 21: 1–5. DOI: 10.1002/cvde.201404329.

- [28] Z. Jiang, R. Song, W. Bi, J. Lu, and T. Tang, (2007) “Polypropylene as a carbon source for the synthesis of multi�walled carbon nanotubes via catalytic combustion" Car�bon 45(2): 449–458. DOI: 10.1016/j.carbon.2006.08. 012.

- [29] C. Zhuo, H. Richter, and Y. A. Levendis, (2018) “Car�bon nanotube production from Ethylene in CO2/N2 envi�ronments" Journal of Energy Resources Technology 140(8): 085001. DOI: 10.1115/1.4039328.

- [30] A. Hussain, Y. Liao, Q. Zhang, E.-X. Ding, P. Laiho, S. Ahmad, N. Wei, Y. Tian, H. Jiang, and E. I. Kaup�pinen, (2018) “Floating catalyst CVD synthesis of single walled carbon nanotubes from ethylene for high perfor�mance transparent electrodes" Nanoscale 10(20): 9752– 9759. DOI: 10.1039/C8NR00716K.

- [31] T. Vergunst, F. Kapteijn, and J. Moulijn, (2002) “Prepa�ration of carbon-coated monolithic supports" Carbon 40(11): 1891–1902. DOI: 10.1016/S0008-6223(02)00034- 9.

- [32] M. R. Malekbala, S. Soltani, S. Abdul Rashid, L. C. Abdullah, and T. S. Y. Choong, (2019) “Study the ef�fect of various wash-coated metal oxides over synthesized carbon nanofibers coated monolith substrates" Plos one 14(7): e0219936. DOI: 10.1371/journal.pone.0219936.

- [33] M. H. Rümmeli, A. Bachmatiuk, F. Börrnert, F. Schäf�fel, I. Ibrahim, K. Cendrowski, G. Simha-Martynkova, D. Plachá, E. Borowiak-Palen, G. Cuniberti, et al., (2011) “Synthesis of carbon nanotubes with and without catalyst particles" Nanoscale research letters 6: 1–9. DOI: 10.1186/1556-276X-6-303.

- [34] Y. D. Lim, A. V. Avramchuck, D. Grapov, C. W. Tan, B. K. Tay, S. Aditya, and V. Labunov, (2017) “En�hanced carbon nanotubes growth using nickel/ferrocene�hybridized catalyst" ACS omega 2(9): 6063–6071. DOI: 10.1021/acsomega.7b00858.

- [35] J. Meng, Z. Miao, J. Zhang, Z. Wang, R. Zhang, L. Xu, L. Diao, J. Zhou, and S. Zhuo, (2023) “One-step synthe�sis of N-doped carbon nanotubes-encapsulated Ni nanopar�ticles for efficient electrochemical CO2 reduction to CO" Journal of Alloys and Compounds 939: 168798.

- [36] Q. Liu, B. Bian, J. Fan, and J. Yang, (2018) “Cobalt doped Ni based ordered mesoporous catalysts for CO2 methanation with enhanced catalytic performance" inter�national journal of hydrogen energy 43(10): 4893– 4901. DOI: 10.1016/j.ijhydene.2018.01.132.

- [37] C.-M. Chen, Y.-M. Dai, J. G. Huang, and J.-M. Jehng, (2006) “Intermetallic catalyst for carbon nan�otubes (CNTs) growth by thermal chemical vapor deposi�tion method" Carbon 44(9): 1808–1820. DOI: 10.1016/j.carbon.2005.12.043.

- [38] S. Hosseini, H. Moghaddas, S. M. Soltani, and S. Kheawhom, (2020) “Technological applications of hon�eycomb monoliths in environmental processes: a review" Process Safety and Environmental Protection 133: 286–300. DOI: 10.1016/j.psep.2019.11.020.

- [39] O. Qistina, A. Salmiaton, T. S. Choong, Y. H. Taufiq�Yap, and S. Izhar, (2020) “Optimization of carbon nanotube-coated monolith by direct liquid injection chemi�cal vapor deposition based on taguchi method" Catalysts 10(1): 67. DOI: 10.3390/catal10010067.

- [40] T. A. Nijhuis, A. E. Beers, T. Vergunst, I. Hoek, F. Kapteijn, and J. A. Moulijn, (2001) “Preparation of monolithic catalysts" Catalysis Reviews 43(4): 345–380. DOI: 10.1081/CR-120001807.

- [41] J. Liu. “Carbon nanotubes developed on ceramic con�stituents through chemical vapour deposition". (phdthe�sis). Loughborough University, 2012.

- [42] W. Gao, Y. Wan, Y. Dou, and D. Zhao, (2011) “Synthe�sis of partially graphitic ordered mesoporous carbons with high surface areas" Advanced Energy Materials 1(1): 115–123. DOI: 10.1002/aenm.201000009.

- [43] N. Saifuddin, A. Raziah, and A. Junizah, (2013) “Car�bon nanotubes: a review on structure and their interac�tion with proteins" Journal of Chemistry 2013: DOI: 10.1155/2013/676815.

- [44] C. He, N. Zhao, X. Du, C. Shi, J. Li, and F. He, (2008) “Characterization of bamboo-shaped CNTs prepared us�ing deposition-precipitation catalyst" Materials Science and Engineering: A 479(1-2): 248–252. DOI: 10.1016/j.msea.2007.06.048.

- [45] R. Baker, J. Chludzinski Jr, N. Dudash, and A. Simoens, (1983) “The formation of filamentous carbon from decomposition of acetylene over vanadium and molyb�denum" Carbon 21(5): 463–468. DOI: 10.1016/0008-6223(83)90138-0.

- [46] A. Oberlin, M. Endo, and T. Koyama, (1976) “Fila�mentous growth of carbon through benzene decomposi�tion" Journal of crystal growth 32(3): 335–349. DOI: 10.1016/0022-0248(76)90115-9.

- [47] F. Haniyeh, A. Abdollah, and D. Abolghasem, (2013) “Controlled growth of well-Aligned carbon nanotubes, elec�trochemical modification and electrodeposition of multiple shapes of gold nanostructures" Materials Sciences and Applications 2013: DOI: 10.4236/msa.2013.411083.

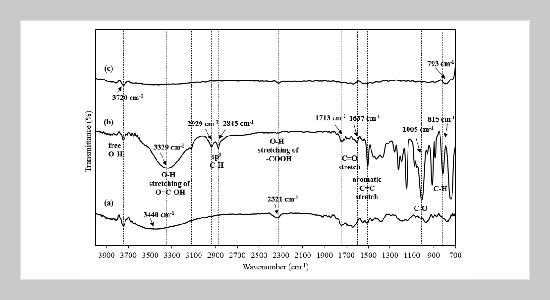

- [48] A. Munajad, C. Subroto, and Suwarno, (2018) “Fourier transform infrared (FTIR) spectroscopy analy�sis of transformer paper in mineral oil-paper composite insulation under accelerated thermal aging" Energies 11(2): 364. DOI: 10.3390/en11020364.

- [49] V. Gupta and T. A. Saleh, (2011) “Syntheses of carbon nanotube-metal oxides composites; adsorption and photo�degradation" Carbon Nanotubes-From Research to Applications 17: 295–312. DOI: 10.5772/18009.

- [50] M. A. Atieh, O. Y. Bakather, B. Al-Tawbini, A. A. Bukhari, F. A. Abuilaiwi, M. B. Fettouhi, et al., (2010) “Effect of carboxylic functional group functionalized on car�bon nanotubes surface on the removal of lead from water" Bioinorganic chemistry and applications 2010: DOI: 10.1155/2010/603978.

- [51] F. A. Azri, R. Sukor, R. Hajian, N. A. Yusof, F. A. Bakar, and J. Selamat, (2017) “Modification strategy of screen-printed carbon electrode with functionalized multi�walled carbon nanotube and chitosan matrix for biosensor development" Asian Journal of Chemistry 29(1): 31. DOI: 10.14233/ajchem.2017.20104.

- [52] J. Liang, Z. Wu, H. Lei, X. Xi, T. Li, and G. Du, (2017) “The reaction between furfuryl alcohol and model com�pound of protein" Polymers 9(12): 711. DOI: 10.3390/polym9120711.

- [53] D. Vélez, W. Magalhães, and G. Capobianco, (2018) “Carbon fiber from fast pyrolysis bio-oil" Science and Technology of Materials 30: 16–22. DOI: 10.1016/j.stmat.2018.10.001.

- [54] A. I. Osman, C. Farrell, A. H. Al-Muhtaseb, J. Har�rison, and D. W. Rooney, (2020) “The production and application of carbon nanomaterials from high alkali sili�cate herbaceous biomass" Scientific reports 10(1): 2563. DOI: 10.1038/s41598-020-59481-7.

- [55] R. Yudianti, H. Onggo, Y. Saito, T. Iwata, J.-i. Azuma, et al., (2011) “Analysis of functional group sited on multi-wall carbon nanotube surface" The Open Materials Science Journal 5(1): DOI: 10.2174/1874088X01105010242.

- [56] M. W. Lee, M. A. S. M. Haniff, A. S. Teh, D. C. Bien, and S. K. Chen, (2015) “Effect of Co and Ni nanoparti�cles formation on carbon nanotubes growth via PECVD" Journal of Experimental Nanoscience 10(16): 1232–1241. DOI: 10.1080/17458080.2014.994679.

- [57] M. E. Birch, T. A. Ruda-Eberenz, M. Chai, R. An�drews, and R. L. Hatfield, (2013) “Properties that in�fluence the specific surface areas of carbon nanotubes and nanofibers" Annals of occupational hygiene 57(9): 1148–1166. DOI: 10.1093/annhyg/met042.

- [58] M. Thommes, K. Kaneko, A. V. Neimark, J. P. Olivier, F. Rodriguez-Reinoso, J. Rouquerol, and K. S. Sing, (2015) “Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report)" Pure and applied chem�istry 87(9-10): 1051–1069. DOI: 10.1515/pac-2014-1117.

- [59] L. Di, H. Yang, T. Xian, and X. Chen, (2018) “Con�struction of Z-scheme g-C3N4/CNT/Bi2Fe4O9 compos�ites with improved simulated-sunlight photocatalytic ac�tivity for the dye degradation" Micromachines 9(12): 613. DOI: 10.3390/mi9120613.

- [60] Z. Tian, C. Liu, Q. Li, J. Hou, Y. Li, and S. Ai, (2015) “Nitrogen-and oxygen-functionalized carbon nanotubes supported Pt-based catalyst for the selective hydrogenation of cinnamaldehyde" Applied Catalysis A: General 506: 134–142. DOI: 10.1016/j.apcata.2015.08.023.

- [61] D.-Y. Kang and J. H. Moon, (2014) “Carbon nanotube balls and their application in supercapacitors" ACS ap�plied materials & interfaces 6(1): 706–711. DOI: 10.1021/am404960r.

- [62] H. A. Asmaly, B. Abussaud, T. A. Saleh, V. K. Gupta, M. A. Atieh, et al., (2015) “Ferric oxide nanoparticles decorated carbon nanotubes and carbon nanofibers: from synthesis to enhanced removal of phenol" Journal of Saudi Chemical Society 19(5): 511–520. DOI: 10.1016/j.jscs.2015.06.002.

- [63] F. M. Anjalin, (2014) “Synthesis and characterization of MWCNTs/PVDF nanocomposite and its electrical stud�ies" Der Pharma Chemica 6(1): 354–359.

- [64] E. Soghrati, M. Kazemeini, A. Rashidi, and K. J. Jozani, (2014) “Development of a structured monolithic support with a CNT washcoat for the naphtha HDS pro�cess" Journal of the Taiwan Institute of Chemical Engineers 45(3): 887–895. DOI: 10.1016/j.jtice.2013.08.009.