- [1] W. Zeng, M. Cai, P. Wang, T. Lu, and F. Yao, (2020) “Application of laser ultrasonic technique for detecting weld defect based on FDST method" Optik 221: 165366. DOI: 10.1016/j.ijleo.2020.165366.

- [2] W.J. Shao, Y. Huang, and Y. Zhang, (2018) “A novel weld seam detection method for space weld seam of narrow butt joint in laser welding" Optics & Laser Technology 99: 39–51. DOI: 10.1016/j.optlastec.2017.09.

- [3] Y. Lu, Z. Zhu, A. Yin, X. Xu, Z. Zhang, and X. Shu, (2023) “Evaluation of corrosion resistance of 316L stain less steel by laser ultrasonic nondestructive testing technology" Materials Research Express 10(9): 096519. DOI: 10.1088/2053-1591/acf6ae.

- [4] X. Kou, C. Pei, T. Liu, S. Wu, T. Liu, and Z. Chen, (2021) “Noncontact testing and imaging of internal defects with a new Laser-ultrasonic SAFT method" Ap plied Acoustics 178: 107956. DOI: 10.1016/j.apacoust.2021.107956.

- [5] G. Davis, R. Nagarajah, S. Palanisamy, R. A. R. Rashid, P. Rajagopal, and K. Balasubramaniam, (2019) “Laser ultrasonic inspection of additive manufactured components" The International Journal of Advanced Manufacturing Technology 102(5): 2571 2579. DOI: 10.1007/s00170-018-3046-y.

- [6] N. Okuyama, K. Nomura, T. Sano, K. Kadota, S. Nitta, T. Era, and S. Asai, (2023) “Study on Detecting Method of Internal Defects by Laser Ultrasonics in Lap Joint Welding of Galvanized Steel Sheet and Finite Element Analysis of Its Detectability" Applied Sciences 13(20): 11515. DOI: 10.3390/app132011515.

- [7] S. Nothdurft, A. Springer, S. Kaierle, H. Ohrdes, J. Twiefel, J. Wallaschek, M. Mildebrath, H. J. Maier, T. Hassel, and L. Overmeyer, (2018) “Laser welding of dissimilar low-alloyed steel-steel butt joints and the effects of beam position and ultrasound excitation on the microstructure" Journal of Laser Applications 30(3): DOI: 10.2351/1.5040607.

- [8] L. Ding, Q. Lu, S. Liu, R. Xu, X. Yan, X. Xu, M. Lu, and Y. Chen, (2022) “Quality inspection of micro solder joints in laser spot welding by laser ultrasonic method" Ultrasonics 118: 106567. DOI: 10.1016/j.ultras.2021.106567.

- [9] H. Alqahtani and A. Ray, (2024) “Convolutional neural network for risk assessment in polycrystalline alloy structures via ultrasonic testing" Fatigue Fracture of Engineering Materials Structures 47(1): 140–152. DOI: 10.1111/ffe.14172.

- [10] S.-H. Park, J.-Y. Hong, T. Ha, S. Choi, and K.-Y. Jhang, (2021) “Deep learning-based ultrasonic testing to evaluate the porosity of additively manufactured parts with rough surfaces" Metals 11(2): 290. DOI: 10.3390/met11020290.

- [11] N. Munir, H. -J. Kim, J. Park, S. -J. Song, and S. -S. Kang, (2019) “Convolutional neural network for ultrasonic weldment flaw classification in noisy conditions" Ultrasonics 94: 74–81. DOI: 10.1016/j.ultras.2018.12.001.

- [12] J. Zhao, T. Hu, and Q. Zhang, (2022) “A wavelet packet transform and convolutional neural network method based ultrasonic detection signals recognition of concrete" Sensors 22(10): 3863. DOI: 10.3390/s22103863.

- [13] T. ZHU, B. Song, J. Mao, and G. LIAN, (2022) “PAUT data intelligent analysis method of welding seams based on deep learning" Journal of Beijing University of Aeronautics and Astronautics 48(3): 504–513. DOI: 10.13700/j.bh.1001-5965.2020.0578.

- [14] Y. Yan, Y. Chen, P. Jia, et al., (2020) “Numerical simulation of ultrasonic waves generated by laser in plate" Applied Laser 40(1): 169–175. DOI: 10.14128/j.cnki. al.20204001.169.

- [15] Z. Yang, H. Yang, T. Tian, D. Deng, M. Hu, J. Ma, D. Gao, J. Zhang, S. Ma, L. Yang, et al., (2023) “A review on guided-ultrasonic-wave-based structural health monitoring: From fundamental theory to machine learning techniques" Ultrasonics 133: 107014. DOI: 10.1016/j.ultras.2023.107014.

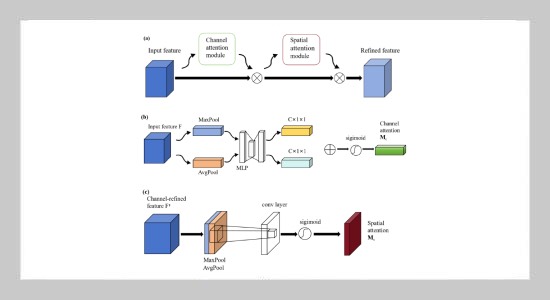

- [16] H. Fu, G. Song, and Y. Wang, (2021) “Improved YOLOv4 marine target detection combined with CBAM" Symmetry 13(4): 623. DOI: 10.3390/sym13040623.

- [17] H. Guo, B. Zheng, and H. Liu, (2017) “Numerical simulation and experimental research on interaction of micro defects and laser ultrasonic signal" Optics & Laser Technology 96: 58–64. DOI: 10.1016/j.optlastec.2017.04.004.

- [18] W. Zeng, X. Zou, and F. Yao, (2020) “Finite element simulation of phased array laser-generated surface acoustic wave for identification surface defects" Optik 224: 165733. DOI: 10.1016/j.ijleo.2020.165733.

- [19] T. Wang, C. Lu, Y. Sun, M. Yang, C. Liu, and C. Ou, (2021) “Automatic ECG classification using continuous wavelet transform and convolutional neural network" Entropy 23(1): 119. DOI: 10.3390/e23010119.

- [20] R. He, K. Wang, N. Zhao, Y. Liu, Y. Yuan, Q. Li, and H. Zhang, (2018) “Automatic detection of atrial fibrillation based on continuous wavelet transform and 2D convolutional neural networks" Frontiers in physiology 9: 1206. DOI: 10.3389/fphys.2018.01206.

- [21] S. Zhang, Z. Liu, Y. Chen, Y. Jin, and G. Bai, (2023) “Selective kernel convolution deep residual network based on channel-spatial attention mechanism and feature fusion for mechanical fault diagnosis" ISA transactions 133: 369–383. DOI: 10.1016/j.isatra.2022.06.035.