- [1] S. K. Sharma, H. Baral, Y. Laumonier, B. Okarda, H. Purnomo, and P. Pacheco, (2019) “Ecosystem ser vices under future oil palm expansion scenarios in West Kalimantan, Indonesia" Ecosystem Services 39: DOI: 10.1016/j.ecoser.2019.100978.

- [2] J. M.L.Thoe, N. Surugau, and H. L. H. Chong, (2019) “Application of Oil Palm EmptyFruitBunchasAdsorbent: AReview" Transactions on Science and Technology 6: 9–26.

- [3] A. Demirba¸s and G. Arin, (2010) “An overview of biomass pyrolysis" Energy Sources 24(5): 471–482. DOI: 10.1080/00908310252889979.

- [4] M.Raju,A.Tambunan,andR.Setiawan,(2016)“Char acterization of charcoal and pyrolysis gases of palm oil waste (in Indonesian)" Jurnal Keteknikan Pertanian 4(2): DOI: 10.19028/jtep.04.2.p153-160.

- [5] U.Hasanudin, R. Sugiharto, A. Haryanto, T. Setiadi, and K. Fujie, (2015) “Palm oil mill effluent treatment and utilization to ensure the sustainability of palm oil industries" Water Science and Technology 72(7): DOI: 10.2166/wst.2015.311.

- [6] M.Saidu, A. Yuzir, M. R. Salim, Salmiati, S. Azman, and N. Abdullah, (2013) “Influence of palm oil mill ef f luent as inoculum on anaerobic digestion of cattle manure for biogas production" Bioresource Technology 141: DOI: 10.1016/j.biortech.2013.03.111.

- [7] Z. S. Lee, S. Y. Chin, J. W. Lim, T. Witoon, and C. K. Cheng, (2019) “Treatment technologies of palm oil mill ef f luent (POME)and olive mill wastewater (OMW): A brief review" Environmental Technology and Innovation 15: 1–19. DOI: 10.1016/j.eti.2019.100377.

- [8] U.Hasanudin, (2018) “Palm oil mill effluent recycling system for sustainable palm oil industries" Asian Jour nal of Environmental Biotechnology 2(1):

- [9] N.Z.Zainuri, N. H. H. Hairom, D. A. B. Sidik, A. L. Desa, N. Misdan, N. Yusof, and A. W. Mohammad, (2018) “Palm oil mill secondary effluent (POMSE) treat ment via photocatalysis process in presence of ZnO-PEG nanoparticles" Journal of Water Process Engineering 26: 10–16. DOI: 10.1016/j.jwpe.2018.08.009.

- [10] N.Darajeh,A.Idris,H.R.FardMasoumi,A.Nourani, P. Truong, and N. A. Sairi, (2016) “Modeling BOD and CODremoval from Palm Oil Mill Secondary Effluent in f loating wetland by Chrysopogon zizanioides (L.) using response surface methodology" Journal of Environmen tal Management 181(1): 343–352. DOI: 10.1016/j.jenvman.2016.06.060.

- [11] N.S.A.Shahrifun, Norul Nazilah Ab’lah2, Hussain1, and A. Aris3, (2015) “Characterization of palm oil mill secondary effluent (POMSE)." Malaysian Journal of Civil Engineering 27(1): 144–151. DOI: 10.11113/mjce.v27n1.364.

- [12] D. A.B. Sidik, N. H. H. Hairom, and A. W. Moham mad, (2019) “Performance and fouling assessment of dif ferent membrane types in a hybrid photocatalytic mem brane reactor (PMR) for palm oil mill secondary efflu ent (POMSE) treatment" Process Safety and Environ mental Protection 130(2019): 265–274. DOI: 10.1016/j.psep.2019.08.018.

- [13] M.M.A.Aziz, K. A. Kassim, M. ElSergany, S. Anuar, M. E. Jorat, H. Yaacob, A. Ahsan, M. A. Imteaz, and Arifuzzaman. Recent advances on palm oil mill effluent (POME) pretreatment and anaerobic reactor for sustain able biogas production. 2020. DOI: 10.1016/j.rser.2019.109603.

- [14] S. Safari, M. Azadi Aghdam, and H. R. Kariminia, (2016) “Electrocoagulation for COD and diesel removal from oily wastewater" International Journal of Envi ronmental Science and Technology 13(1): 231–242. DOI: 10.1007/s13762-015-0863-5.

- [15] F.Zhu,Y.M.Zheng,B.G.Zhang,andY.R.Dai,(2021) “A critical review on the electrospun nanofibrous mem branes for the adsorption of heavy metals in water treat ment" Journal of Hazardous Materials 401: 123608. DOI: 10.1016/J.JHAZMAT.2020.123608.

- [16] F.Mbarki,T.Selmi, A. Kesraoui, and M.Seffen, (2022) “Low-cost activated carbon preparation from Corn stig mata fibers chemically activated using H3PO4, ZnCl2 and KOH: Study of methylene blue adsorption, stochas tic isotherm and fractal kinetic" Industrial Crops and Products 178: 114546. DOI: 10.1016/J.INDCROP.2022.114546.

- [17] Q. Wu,G.Zhang, M.Gao, L. Huang, L. Li, S. Liu, C. Xie, Y. Zhang, and S. Yu, (2019) “N-doped porous car bon from different nitrogen sources for high-performance supercapacitors and CO2 adsorption" Journal of Al loys and Compounds 786: 826–838. DOI: 10.1016/J.JALLCOM.2019.02.052.

- [18] F. Shen, J. Liu, D. Wu, Y. Dong, F. Liu, and H. Huang, (2019) “Design of O2/SO2 dual-doped porous carbon as superior sorbent for elemental mercury removal from flue gas" Journal of Hazardous Materials 366: 321–328. DOI: 10.1016/J.JHAZMAT.2018.12.007.

- [19] Desi, A. Suharman, and R. Vinsiah, (2015) “The effect of carbonisation temperature variation to the adsorption ability of rubber fruit shell activated carbon" Prosiding SEMIRATA2015: 294–303.

- [20] A. E. A. Nayl, R. A. Elkhashab, T. El Malah, S. M. Yakout, M. A. El-Khateeb, M. M. Ali, and H. M. Ali, (2017) “Adsorption studies on the removal of COD and BOD from treated sewage using activated carbon pre pared from date palm waste" Environmental Science and Pollution Research 24(28): 22284–22293. DOI: 10.1007/s11356-017-9878-4.

- [21] H.N.J. Hoong and N.Ismail, (2018) “Removal of dye in wastewater by adsorption-coagulation combined sys tem with hibiscus sabdariffa as the coagulant" MATEC WebofConferences 152: DOI: 10.1051/matecconf/201815201008.

- [22] Günes, D. Elçin Çifçi Deniz Izlen, and A. Riza, (2021) “Removal of COD, aromaticity and color of a pretreated chemical producing industrial wastewater: A comparison between adsorption, ozonation, and advanced oxidation processes" Turkish Journal of Chemistry 45(3): 551 565. DOI: 10.3906/kim-2010-48.

- [23] A. H. Jawad, A. Saud Abdulhameed, L. D. Wil son, S. S. A. Syed-Hassan, Z. A. ALOthman, and M. Rizwan Khan, (2021) “High surface area and meso porous activated carbon from KOH-activated dragon fruit peels for methylene blue dye adsorption: Optimization and mechanism study" Chinese Journal of Chemical En gineering 32: 281–290. DOI: 10.1016/J.CJCHE.2020.09.070.

- [24] T. E. S. P. Rahayu, R. Dwityaningsih, and U. Ulikaryani, (2022) “Effect of Carbonization Time on Moisture and Ash Content and Adsorption Ability of Hydrochloric Acid Activated Nipah Shell Charcoal" Infotekmesin 13(1): 124–130. DOI: 10.35970/infotekmesin.v13i1.1027.

- [25] E. Windiastuti, N. S. Indrasti, U. Hasanudin, Y. Bindar, and S. Suprihatin, (2023) “The Influence of Pre treatment and Post Treatment with Alkaline Activators on the Adsorption Ability of Biochar from Palm Oil Empty Fruit" Journal of Ecological Engineering 24(10): 242 251. DOI: 10.12911/22998993/170719.

- [26] SuprihatinandN.S.Indrasti,(2010)“Removalofheavy metals from laboratory liquid waste using precipitation and adsorption methods (in Indonesia)" Makara journal of Sains 14(1): 44–50.

- [27] I. Sailah, F. Reyhanto, T. Puspaningrum, M. Romli, S. Suprihatin, and N. S. Indrasti, (2020) “Improving the Quality of Anaerobically-Pretreated Palm Oil Mill Ef f luent Using Electrocoagulation" Journal of Ecological Engineering 22(1): 112–124. DOI: 10.12911/22998993/128867.

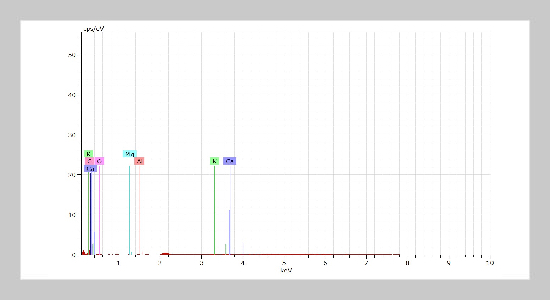

- [28] X. Ma, B. Zhou, A. Budai, A. Jeng, X. Hao, D. Wei, Y. Zhang, and D. Rasse, (2016) “Study of biochar proper ties by Scanning Electron Microscope– Energy Dispersive X-Ray Spectroscopy (SEM-EDX)" Communications in Soil Science and Plant Analysis 47(5): 593–601. DOI: 10.1080/00103624.2016.1146742.

- [29] Isroi, A. Cifriadi, T. Panji, N. A. Wibowo, and K. Syamsu, (2017) “Bioplastic production from cellulose of oil palm empty fruit bunch" IOP Conference Se ries: Earth and Environmental Science 65(1): DOI: 10.1088/1755-1315/65/1/012011.

- [30] I. N. Mohammad, C. M.Ongkudon, and M.Misson, (2020) “Physicochemical properties and lignin degrada tion of thermal-pretreated oil palm empty fruit bunch" Energies 13(22): 5966. DOI: 10.3390/en13225966.

- [31] S. Kushwaha, G. Sreelatha, and P. Padmaja, (2013) “Physical and chemical modified forms of palm shell: Prepa ration, characterization and preliminary assessment as adsorbents" Journal of Porous Materials 20(1): 21–36. DOI: 10.1007/s10934-012-9571-4.

- [32] S. M. Yakout and G. S. El-Deen, (2016) “Characteriza tion of activated carbon prepared by phosphoric acid acti vation of olive stones" Arabian Journal of Chemistry 9: S1155–S1162. DOI: 10.1016/J.ARABJC.2011.12.002.

- [33] N. Claoston, A. Samsuri, M. Ahmad Husni, and M. MohdAmran,(2014) “Effects of pyrolysis temperature onthe physicochemical properties of empty fruit bunch and rice husk biochars" Waste Management & Research 32(4): 331–339. DOI: 10.1177/0734242X14525822.

- [34] X.He,Z.Liu,W.Niu,L.Yang,T.Zhou,D.Qin,Z.Niu, and Q. Yuan, (2018) “Effects of pyrolysis temperature on the physicochemical properties of gas and biochar obtained from pyrolysis of crop residues" Energy 143: 746–756. DOI: 10.1016/J.ENERGY.2017.11.062.

- [35] S. A. Zamani, R. Yunus, A. W. Samsuri, M. A. Salleh, and B. Asady, (2017) “Removal of Zinc from Aqueous Solution by Optimized Oil Palm Empty Fruit Bunches Biochar as Low Cost Adsorbent" Bioinorganic Chem istry and Applications 2017: DOI: 10.1155/2017/7914714.

- [36] Aziz, M. A. b. M. Nor, S. F. b. A. Manaf, and F. Hamzah, (2015) “Suitability of biochar produced from biomass waste as soil amendment" Procedia- Social and Behavioral Sciences 195: 2457–2465. DOI: 10.1016/j.sbspro.2015.06.288.

- [37] B. Mallesh, (2018) “A review of electrocoagulation pro cess for wastewater treatment" International Journal of ChemTech Research 11(03): 289–302. DOI: 10.20902/ijctr.2018.110333.

- [38] A. A. Halim, N. N. Z. Abidin, N. Awang, A. Ithnin, M. S. Othman, and M. I. Wahab, (2011) “Ammonia and CODremoval from synthetic leachate using rice husk composite adsorbent" Journal of Urban and Environ mental Engineering 5(1): 24–31. DOI: 10.4090/juee.2011.v5n1.024031.

- [39] L. Cundari, A. A. Suhendra, S. R. Indahsari, M. Asnari, B. D. Afrah, A. Gunawan, and M. M. Al fatih, (2022) “The effectiveness of water hyacinth (Ei chornia crassipes) activated carbon in processing tem peh liquid waste (in Indonesian)" JST (Jurnal Sains dan Teknologi) 11(2): 403–410. DOI: 10.23887/jstundiksha.v11i2.49422.

- [40] S. Liang, X. Guo, N. Feng, and Q. Tian, (2010) “Isotherms, kinetics and thermodynamic studies of adsorp tion of Cu2+ from aqueous solutions by Mg2+/K+ type orange peel adsorbents" Journal of Hazardous Materi als 174(1-3): 756–762. DOI: 10.1016/j.jhazmat.2009.09.116.

- [41] L.Maghfiroh,I.Ulfin,andH.Juwono,(2016)“Effectof pHon the Reduction of Remazol Yellow FG Dyes by Nata De Coco Bacterial Cellulose Adsorbent (In Indonesian)" Jurnal Sains dan Seni ITS 5(2): 2337–3520. DOI: 10.12962/j23373520.v5i2.17719.

- [42] M. M. Silva, M. M. Oliveira, M. C. Avelino, M. G. Fonseca, R. K. Almeida, and E. C. Silva Filho, (2012) “Adsorption of an industrial anionic dye by modified-KSF montmorillonite: Evaluation of the kinetic, thermody namic and equilibrium data" Chemical Engineering Journal 203: 259–268. DOI: 10.1016/J.CEJ.2012.07.009.

- [43] C. Wang, M.Luo, C. Xie, K. Li, F. Hang, C. Shi, and W. O. Doherty, (2022) “Effective Adsorption of Col orants from Sugarcane Juice by Bagasse-Based Biochar Hydroxyapatite Composite" Foods 11(14): DOI: 10.3390/foods11142171.

- [44] K. Crombie, O. Mašek, S. P. Sohi, P. Brownsort, and A. Cross, (2013) “The effect of pyrolysis conditions on biochar stability as determined by three methods" GCB Bioenergy 5(2): 122–131. DOI: 10.1111/gcbb.12030.

- [45] J. Qu, X. Zhang, S. Liu, X. Li, S. Wang, Z. Feng, Z. Wu, L. Wang, Z. Jiang, and Y. Zhang, (2022) “One step preparation of Fe/N co-doped porous biochar for chromium(VI) and bisphenol a decontamination in wa ter: Insights to co-activation and adsorption mechanisms" Bioresource Technology 361: 127718. DOI: 10.1016/J. BIORTECH.2022.127718.

- [46] E.Bazrafshan, M.R.Alipour,andA.H.Mahvi,(2016) “Textile wastewater treatment by application of combined chemical coagulation, electrocoagulation, and adsorption processes" Desalination and Water Treatment 57(20): 9203–9215. DOI: 10.1080/19443994.2015.1027960.

- [47] N. Claoston, A. Samsuri, M. Ahmad Husni, and M. MohdAmran,(2014) “Effects of pyrolysis temperature onthe physicochemical properties of empty fruit bunch and rice husk biochars" Waste Management & Research 32(4): 331–339. DOI: 10.5772/intechopen.75460.