Basori1This email address is being protected from spambots. You need JavaScript enabled to view it., Wan Mohd Farid Wan Mohamad2,3, Noreffendy Tamaldin2,3, Muhd Ridzuan Mansor2,3, Maman Kartaman Ajiriyanto4, Arif Nugroho4, Rosika Kriswarini4, Juan Carlos Sihotang4, Sigit Dwi Yudanto5, Cahaya Rosyidan6, and Ferry Budhi Susetyo7

1Department of Mechanical Engineering, Universitas Nasional, 12520, Indonesia

2Faculty of Mechanical Technology and Engineering, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia

3Centre for Advanced Research on Energy, Universiti Teknikal Malaysia Melaka, Hang Tuah Jaya, 76100 Durian Tunggal, Melaka, Malaysia

4Research Center for Nuclear Material and Radioactive Waste Technology- National Research and Innovation Agency, 15314, Indonesia

5Research Center for Metallurgy- National Research and Innovation Agency, 15314, Indonesia

6Department of Petroleum Engineering, Universitas Trisakti, 11440, Indonesia

7Department of Mechanical Engineering, Universitas Negeri Jakarta, 13220, Indonesia

- [1] X. An, Q. Zhao, and X. Li, (2024) “Feasibility Study of Using Industrial Wind Turbine in Manjil City by En ergy, Exergy, Economic and Exergy Destruction Analy sis" Journal of Applied Science and Engineering 27: 2713–2723. DOI: 10.6180/jase.202406_27(6).0011.

- [2] K.B. M.Kiran, M. S. Indira, and R. Nagaraja, (2022) “Mathematical Modeling and Evaluation of Performance Characteristics of a Hybrid Solar PV and Wind Energy System" Journal of Applied Science and Engineer ing 25: 785–797. DOI: 10.6180/jase.202208_25(4).0014.

- [3] F. Dawood, M. Anda, and G. Shafiullah, (2020) “Hy drogen Production for Energy: An Overview" Interna tional Journal of Hydrogen Energy 45: 3847–3869. DOI: 10.1016/j.ijhydene.2019.12.059.

- [4] I. Puspitasari, N. Wahyudi, Y. A. Fakhrudi, and G. P. Wicaksono, (2021) “Design of Generator HHO Dry Cell Type and Application on 110 CC Engined Vehicles To wards Gas Emissions" Journal of Physics: Conference Series 1845: 012002. DOI: 10.1088/1742-6596/1845/1/012002.

- [5] S. A. Musmar and A. A. Al-Rousan, (2011) “Effect of HHOGas on Combustion Emissions in Gasoline En gines" Fuel 90: 3066–3070. DOI: 10.1016/j.fuel.2011.05.013.

- [6] C.-W. Sun and S.-S. Hsiau, (2018) “Effect of Electrolyte Concentration Difference on Hydrogen Production Dur ing PEM Electrolysis" Journal of Electrochemical Sci ence and Technology 9: 99–108. DOI: 10.5229/JECST.2018.9.2.99.

- [7] I. Hamidah, A. Solehudin, and A. Setiawan, (2016) “Effect of Variation of Kalium Hydroxide Solution Concen tration and Temperature to the Corrosion Resistance of AISI 304, AISI 316, and Copper Alloys in Water Electrol ysis Apparatus" ARPN Journal of Engineering and Applied Science 11: 972–977.

- [8] M. H. Sellami and K. Loudiyi, (2017) “Electrolytes Behavior during Hydrogen Production by Solar Energy" Renewable and Sustainable Energy Reviews 70: 1331–1335. DOI: 10.1016/j.rser.2016.12.034.

- [9] A. Budiman, M. Yerizam, and Y. Bow, (2021) “De sign of Dry Cell HHO Generator using NaCl Solution for Hydrogen Production" Indonesian Journal of Fun damental And Applied Chemistry (IJFAC) 7: 8–15. DOI: 10.24845/ijfac.v7.i1.8.

- [10] A. B. Vethamony and V. Thangavel, (2023) “Experi ments on the Effect of Temperature on HHO Production by Alkaline Water Electrolysis" Materials Today: Pro ceedings: DOI: 10.1016/j.matpr.2023.03.771.

- [11] A.El Soly, M. El Kady, A. E. F. Farrag, and M. Gad, (2021) “Comparative Experimental Investigation of Oxy hydrogen (HHO) Production Rate using Dry and Wet Cells" International Journal of Hydrogen Energy 46: 12639–12653. DOI: 10.1016/j.ijhydene.2021.01.110.

- [12] B. Basori, W. M. Mohamad, M. R. Mansor, N. Tamaldin, A. Iswandi, M. K. Ajiriyanto, and F. B. Susetyo, (2023) “Effect of KOH Concentration on Corro sion Behavior and Surface Morphology of Stainless Steel 316L for HHO Generator Application" Journal of Elec trochemical Science and Engineering 13: 451–467. DOI: 10.5599/jese.1615.

- [13] M. BenSalah, R. Sabot, E. Triki, L. Dhouibi, P. Re fait, and M. Jeannin, (2014) “Passivity of Sanicro28 (UNS N-08028) Stainless Steel in Polluted Phosphoric Acid at Different Temperatures Studied by Electrochemi cal Impedance Spectroscopy and Mott-Schottky Analysis" Corrosion Science 86: 61–70. DOI: 10.1016/j.corsci.2014.04.056.

- [14] C. Escrivà-Cerdán, E. Blasco-Tamarit, D. M. García García, J. García-Antón, and A. Guenbour, (2012) “Passivation Behaviour of Alloy 31 (UNS N08031) in Pol luted Phosphoric Acid at Different Temperatures" Corro sion Science 56: 114–122. DOI: 10.1016/j.corsci.2011.11.014.

- [15] Z. Wang, Z. Feng, and L. Zhang, (2020) “Effect of High Temperature on the Corrosion Behavior and Pas sive Film Composition of 316 L Stainless Steel in High H2S-containing Environments" Corrosion Science 174: 108844. DOI: 10.1016/j.corsci.2020.108844.

- [16] H. Krungkarnchana and C. Kongvarhodom, (2019) “Low Temperature Corrosion: Oxidation of Carbon Steel and Stainless Steel in Air" Applied Science and En gineering Progress 12: 44–51. DOI: 10.14416/j.ijast.2018.05.001.

- [17] B. Basori, W. Mohamad, N. Tamaldin, M. Mansor, M. Ajiriyanto, S. Yudanto, and F. Susetyo, (2023) “In f luence of Temperature and Azithromycin on the Surface of SS 316L in a KOH Solution" International Journal of Corrosion and Scale Inhibition 12: 258–274. DOI: 10.17675/2305-6894-2023-12-1-15.

- [18] Z. Ahmad, (2006) “Principles of Corrosion Engineering and Corrosion Control": 1–656. DOI: 10.1016/b978-0 7506-5924-6.x5000-4.

- [19] M. Talha, C. Behera, and O. Sinha, (2012) “Potentio dynamic Polarization Study of Type 316L and 316LVM Stainless Steels for Surgical Implants in Simulated Body Fluids" Journal of Chemical and Pharmaceutical Re search 4: 203–208.

- [20] Ž. Z. Tasi´c, M. B. P. Mihajlovi´c, M. B. Radovanovi´c, and M.M.Antonijevi´ c, (2018) “Electrochemical Inves tigations of Copper Corrosion Inhibition by Azithromycin in 0.9% NaCl" Journal of Molecular Liquids 265: 687–692. DOI: 10.1016/j.molliq.2018.03.116.

- [21] F. Arjmand, L. Zhang, and J. Wang, (2017) “Effect of Temperature, Chloride and Dissolved Oxygen Concen tration on the Open Circuit and Transpassive Potential Values of 316L Stainless Steel at High-Temperature Pres surized Water" Nuclear Engineering and Design 322: 215–226. DOI: 10.1016/j.nucengdes.2017.06.048.

- [22] H.Iken, R. Basseguy, A. Guenbour, and A. B. Bachir, (2007) “Classic and Local Analysis of Corrosion Be haviour of Graphite and Stainless Steels in Polluted Phos phoric Acid" Electrochimica Acta 52: 2580–2587. DOI: 10.1016/j.electacta.2006.09.013.

- [23] Z. Wang, L. Zhang, X. Tang, Z.-y. Cui, J.-p. Xue, and M.-x. Lu, (2017) “Investigation of the Deterioration of Passive Films in H2S-containing Solutions" Interna tional Journal of Minerals, Metallurgy, and Materi als 24: 943–953. DOI: 10.1007/s12613-017-1482-6.

- [24] R. D. Monteiro, J. V. D. Wetering, B. Krawczyk, and D. L. Engelberg, (2019) “Corrosion Behaviour of Type 316L Stainless Steel in Hot Caustic Aqueous Environ ments" Metals and Materials International 26: 630–640. DOI: 10.1007/s12540-019-00403-2.

- [25] Y. Yang, L. Guo, and H. Liu, (2011) “The Effect of Tem perature on Corrosion Behavior of SS316L in the Cath ode Environment of Proton Exchange Membrane Fuel Cells" Journal of Power Sources 196: 5503–5510. DOI: 10.1016/j.jpowsour.2011.02.070.

- [26] M.Ridha, S. Fonna, S. Huzni, J. Supardi, and A. Arif f in, (2013) “Atmospheric Corrosion of Structural Steels Exposed in the 2004 Tsunami-affected Areas of Aceh" In ternational Journal of Automotive and Mechanical Engineering 7: 1014–1022. DOI: 10.15282/ijame.7.2012.17.0082.

- [27] X.-x.Fang,H.-z.Zhou,andY.-j.Xue,(2015)“Corrosion Properties of Stainless Steel 316L/Ni-Cu-P Coatings in Warm Acidic Solution" Transactions of Nonferrous Metals Society of China 25: 2594–2600. DOI: 10.1016/S1003-6326(15)63880-8.

- [28] A. Hossain, F. Gulshan, and A. S. W. Kurny, (2015) “Electrochemical Corrosion Behavior of Ni-containing Hy poeutectic Al-Si Alloy" Journal of Electrochemical Science and Engineering 5: 173–179. DOI: 10.5599/jese.174.

- [29] J. Huang, X. Wu, and E.-H. Han, (2009) “Influence of pH on Electrochemical Properties of Passive Films Formed on Alloy 690 in High Temperature Aqueous En vironments" Corrosion Science 51: 2976–2982. DOI: 10.1016/j.corsci.2009.08.002.

- [30] T. Dan, T. Shoji, Z. Lu, K. Sakaguchi, J. Wang, E.-H. Han, and W. Ke, (2010) “Effects of Hydrogen on the An odic Behavior of Alloy 690 at 60 °C" Corrosion Science 52: 1228–1236. DOI: 10.1016/j.corsci.2009.11.039.

- [31] Z. Feng, X. Cheng, C. Dong, L. Xu, and X. Li, (2010) “Passivity of 316L Stainless Steel in Borate Buffer Solution Studied by Mott–Schottky Analysis, Atomic Absorption Spectrometry and X-ray Photoelectron Spectroscopy" Cor rosion Science 52: 3646–3653. DOI: 10.1016/j.corsci.2010.07.013.

- [32] N.Hakiki, S. Boudin, B. Rondot, and M. D. C. Belo, (1995) “The Electronic Structure of Passive Films Formed on Stainless Steels" Corrosion Science 37: 1809–1822. DOI: 10.1016/0010-938X(95)00084-W.

- [33] C. Sunseri, S. Piazza, and F. Di Quarto, (1990) “Pho tocurrent Spectroscopic Investigations of Passive Films on Chromium" Journal of the Electrochemical Society 137: 2411–2417. DOI: 10.1149/1.2086952.

- [34] C. H. Ng, O. Winther-Jensen, C. A. Ohlin, and B. Winther-Jensen, (2015) “Exploration and Optimisation of Poly(2,2-bithiophene) as a Stable Photo-electrocatalyst for Hydrogen Production" Journal of Materials Chem istry A 3: 11358–11366. DOI: 10.1039/c5ta00291e.

- [35] K. Zeng and D. Zhang, (2010) “Recent Progress in Alkaline Water Electrolysis for Hydrogen Production and Applications" Progress in Energy and Combustion Science 36: 307–326. DOI: 10.1016/j.pecs.2009.11.002.

- [36] S. Marini, P. Salvi, P. Nelli, R. Pesenti, M. Villa, M. Berrettoni, G. Zangari, and Y. Kiros, (2012) “Advanced Alkaline Water Electrolysis" Electrochimica Acta 82: 384–391. DOI: 10.1016/j.electacta.2012.05.011.

- [37] W.-X. Chen, (2001) “Kinetics of Hydrogen Evolution Re action on Hydrogen Storage Alloy Electrode in Alkaline Solution and Effects of Surface Modification on the Elec trocatalytic Activity for Hydrogen Evolution Reaction" International Journal of Hydrogen Energy 26: 603 608. DOI: 10.1016/S0360-3199(00)00119-1.

- [38] V. Protsenko, L. Bobrova, T. Butyrina, and F. Danilov, (2019) “Hydrogen Evolution Reaction on Cr-C Electro catalysts Electrodeposited from a Choline Chloride Based Trivalent Chromium Plating Bath" Voprosy Khimii i Khimicheskoi Tekhnologii: 61–66. DOI: 10.32434/ 0321-4095-2019-122-1-61-66.

- [39] Y.-g. Huang, H.-l. Fan, Z.-k. Chen, C.-b. Gu, M.-x. Sun, H.-q. Wang, and Q.-y. Li, (2016) “The Effect of Graphene for the Hydrogen Evolution Reaction in Al kaline Medium" International Journal of Hydrogen Energy 41: 3786–3793. DOI: 10.1016/j.ijhydene.2015.12.113.

- [40] S. Oh, D. Kim, K. Kim, D.-I. Kim, W. Chung, and B.-H. Shin, (2023) “The Effect of Surface Roughness on Re-passivation and Pitting Corrosion of Super Duplex Stainless Steel UNS S 32760" International Journal of Electrochemical Science 18: 100351. DOI: 10.1016/j.ijoes.2023.100351.

- [41] A. Toloei, V. Stoilov, and D. Northwood, (2013) “The Relationship Between Surface Roughness and Corro sion" ASME International Mechanical Engineering Congress and Exposition 56192: V02BT02A054. DOI: 10.1115/IMECE2013-65498.

- [42] S.Cihangir,Y.Say,I. Ozkul,O.Guler,andS.H.Guler, (2022) “Microstructure and Corrosion Investigation of Fe CoCrNiMo0,5(MnAl)0,3 High Entropy Alloy Produced by 316 L Stainless Steel Scrap" Materials Today Com munications 33: 104360. DOI: 10.1016/j.mtcomm.2022.104360.

- [43] C. Ni and L. Lu, (2014) “Electrochemical Impedance and Modelling Studies of the Corrosion of Three Commer cial Stainless Steels in Molten Carbonate" International Journal of Corrosion 2014: 721208. DOI: 10.1155/2014/721208.

- [44] S. Choudhary, R. Kelly, and N. Birbilis, (2024) “On the Origin of Passive Film Breakdown and Metastable Pitting for Stainless Steel 316L" Corrosion Science 230: 111911. DOI: 10.1016/j.corsci.2024.111911.

- [45] G. Jiang, D. Xu, J. Liu, J. Yang, Y. Li, and W. Kuang, (2024) “Corrosion Protection and Failure Mechanism of ZrO2 Coating on Zirconium Alloy Zry-4 under Varied LiOH Concentrations in Lithiated Water at 360 °C/18.5 MPa" Applied Surface Science 650: 159173. DOI: 10.1016/j.apsusc.2023.159173.

- [46] G. Jiang, D. Xu, S. Guo, L. Liu, B. Hao, and M. Wang, (2022) “Corrosion Behavior and Mechanisms of Al2O3 and Mo Coated Zircaloy-4 in High-temperature Lithiated Water" Corrosion Science 201: 110270. DOI: 10.1016/j.corsci.2022.110270.

- [47] R. Santamaria, K. Wang, M. Salasi, M. Iannuzzi, M. Y. Mendoza, and M. Z. Quadir, (2023) “Stress Corrosion Cracking of 316L Stainless Steel Additively Manufac tured with Sinter-based Material Extrusion" Materials 16: 4006. DOI: 10.3390/ma16114006.

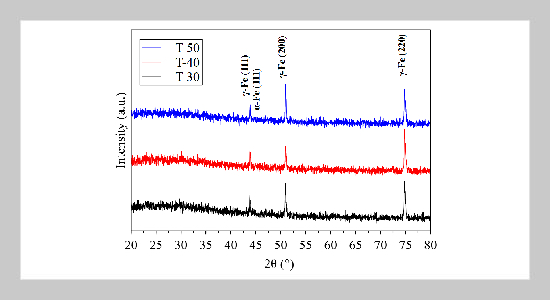

- [48] S.-J. Lee and Y.-K. Lee, (2005) “Quantitative Analyses of Ferrite Lattice Parameter and Solute Nb Content in Low Carbon Microalloyed Steels" Scripta Materialia 52: 973–976. DOI: 10.1016/j.scriptamat.2005.01.028.

- [49] I. Seki and K. Nagata, (2005) “Lattice Constant of Iron and Austenite Including its Supersaturation Phase of Car bon" ISIJ international 45: 1789–1794. DOI: 10.2355/isijinternational.45.1789.

- [50] V. Lobodyuk, Y. Y. Meshkov, and E. Pereloma, (2019) “On Tetragonality of the Martensite Crystal Lattice in Steels" Metallurgical and Materials Transactions A 50: 97–103. DOI: 10.1007/s11661-018-4999-z.